- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

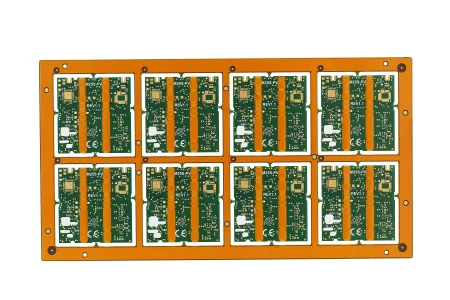

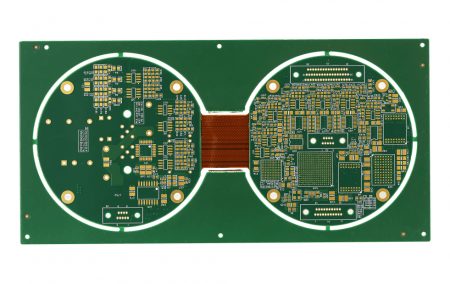

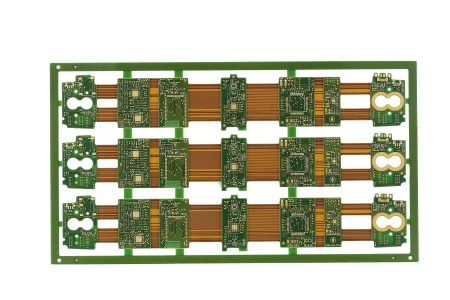

A 14-layer rigid-flex PCB is a printed circuit board that combines the advantages of both rigid and flexible PCBs. It is constructed by stacking multiple layers of rigid and flexible materials, allowing for the integration of multiple circuits into a single board. This document will explore the features and benefits of a 14-layer rigid-flex PCB and its applications in various fields.

A rigid-flex PCB is a multilayer printed circuit board that combines rigid and flexible sections within a single board. The rigid section provides mechanical support and electrical connectivity for the components, while the flexible section enables the board to bend or flex in certain directions. This unique combination of properties allows designers to optimize the performance and functionality of their electronic products.

– Aerospace and Defense: These PCBs are commonly used in aerospace and defense applications due to their enhanced durability, flexibility, and electrical performance. They are often found in aircraft and spacecraft systems, military communication systems, and radar systems.

– Medical Electronics: 14-layer rigid-flex PCBs are used in medical devices such as implantable devices, diagnostic equipment, and surgical tools. Their compact size, flexibility, and reliability make them well-suited for applications that require miniature components and integrated circuits.

– Automotive Electronics: 14-layer rigid-flex PCBs are used in automotive electronics, particularly in modern vehicles with complex electronic systems. They can be found in infotainment systems, control panels, and engine control systems. Their durability, flexibility, and electrical performance make them ideal for automotive applications.

– Industrial Electronics: 14-layer rigid-flex PCBs are used in industrial control systems, robots, and automation equipment. Their compact size, flexibility, and electrical performance make them well-suited for applications where size and weight are critical factors.

A 14-layer rigid-flex PCB is a versatile and high-performance printed circuit board that combines the advantages of both rigid and flexible PCBs. Its combination of flexibility, durability, electrical performance, and compact size makes it an ideal choice for a wide range of applications, particularly in industries where compact size, dynamic movement, and ruggedness are essential. By leveraging the benefits of a rigid-flex PCB, designers can optimize their electronic designs and create innovative and efficient products.

Take Your Projects to New Heights with XPCB Limited

XPCB Limited offers top-notch PCB manufacturing, quick-turnaround prototyping, and turnkey PCBA services designed to make your projects shine. Count on us to bring your ideas to life with efficiency and quality. Your success matters to us, and we’re here to make your innovation journey smooth and rewarding.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve