XPCB Limited: Pioneering Excellence in PCB Manufacturing Equipment

At XPCB Limited, we pride ourselves on being at the forefront of printed circuit board (PCB) manufacturing. Our state-of-the-art equipment and cutting-edge technology ensure that we deliver high-quality, precision-engineered PCBs for all your electronic needs. Whether you’re in the aerospace, automotive, medical, or consumer electronics industry, our advanced manufacturing capabilities cater to diverse requirements and specifications.

Our PCB Manufacturing Process

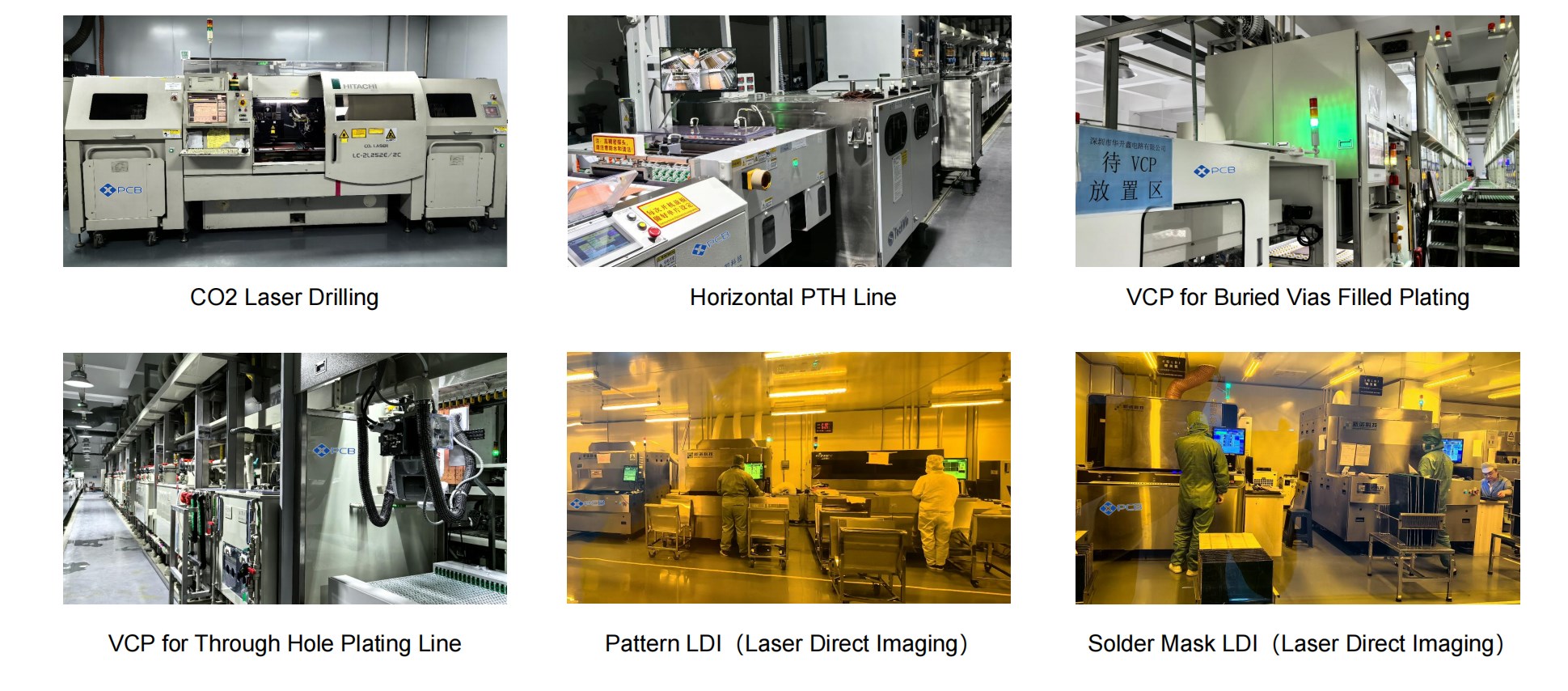

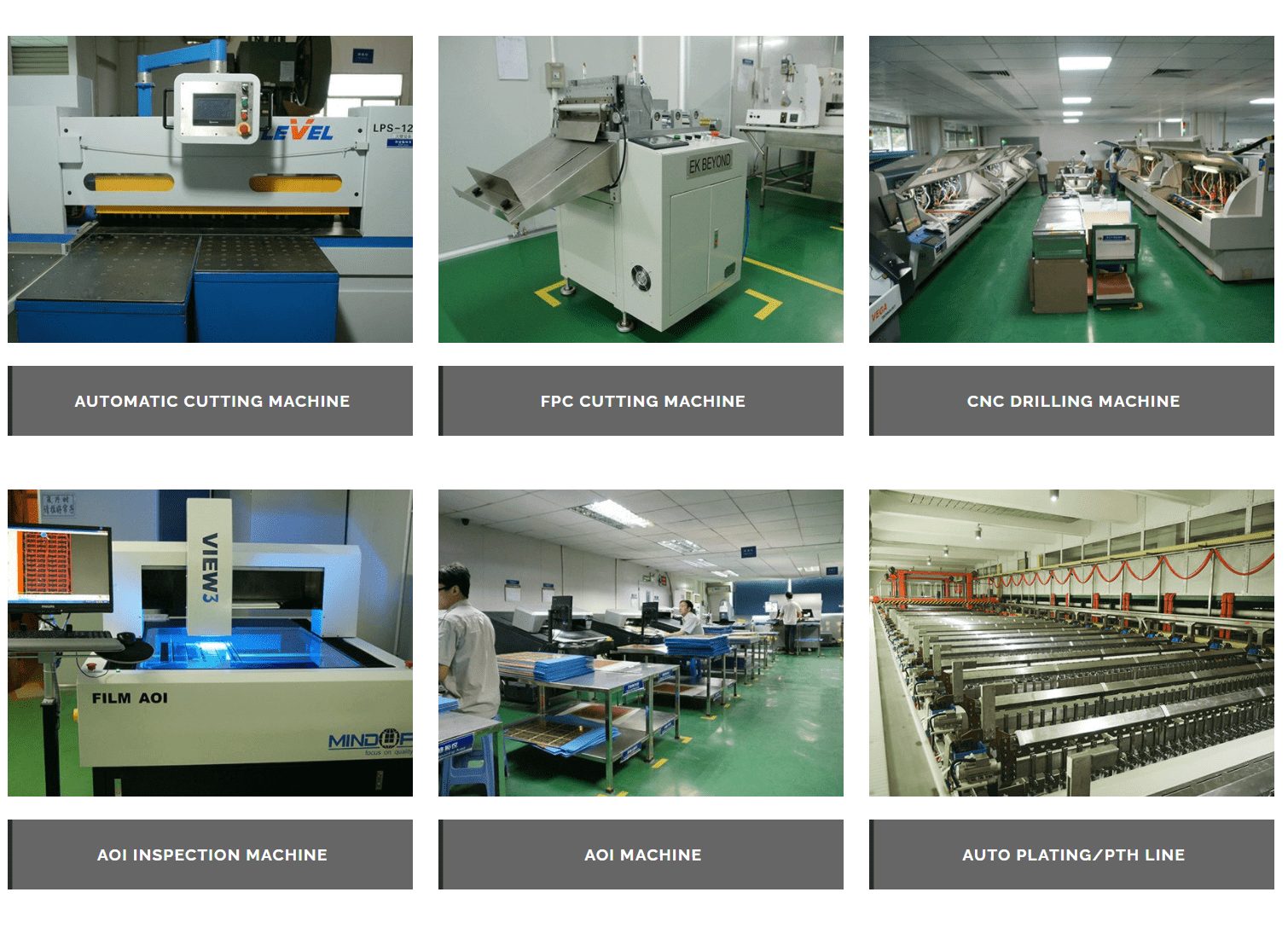

Our circuit board production line is equipped with the latest in PCB manufacturing equipment, enabling us to handle projects of varying complexities with ease. From single-layer to multi-layer boards, our facility is designed to produce PCBs that meet the highest industry standards.

- Design and Prototyping

Our journey begins with advanced CAD systems for precise PCB design. Our rapid prototyping equipment allows for quick turnaround times, essential for validating designs before full-scale production. - Layer Production

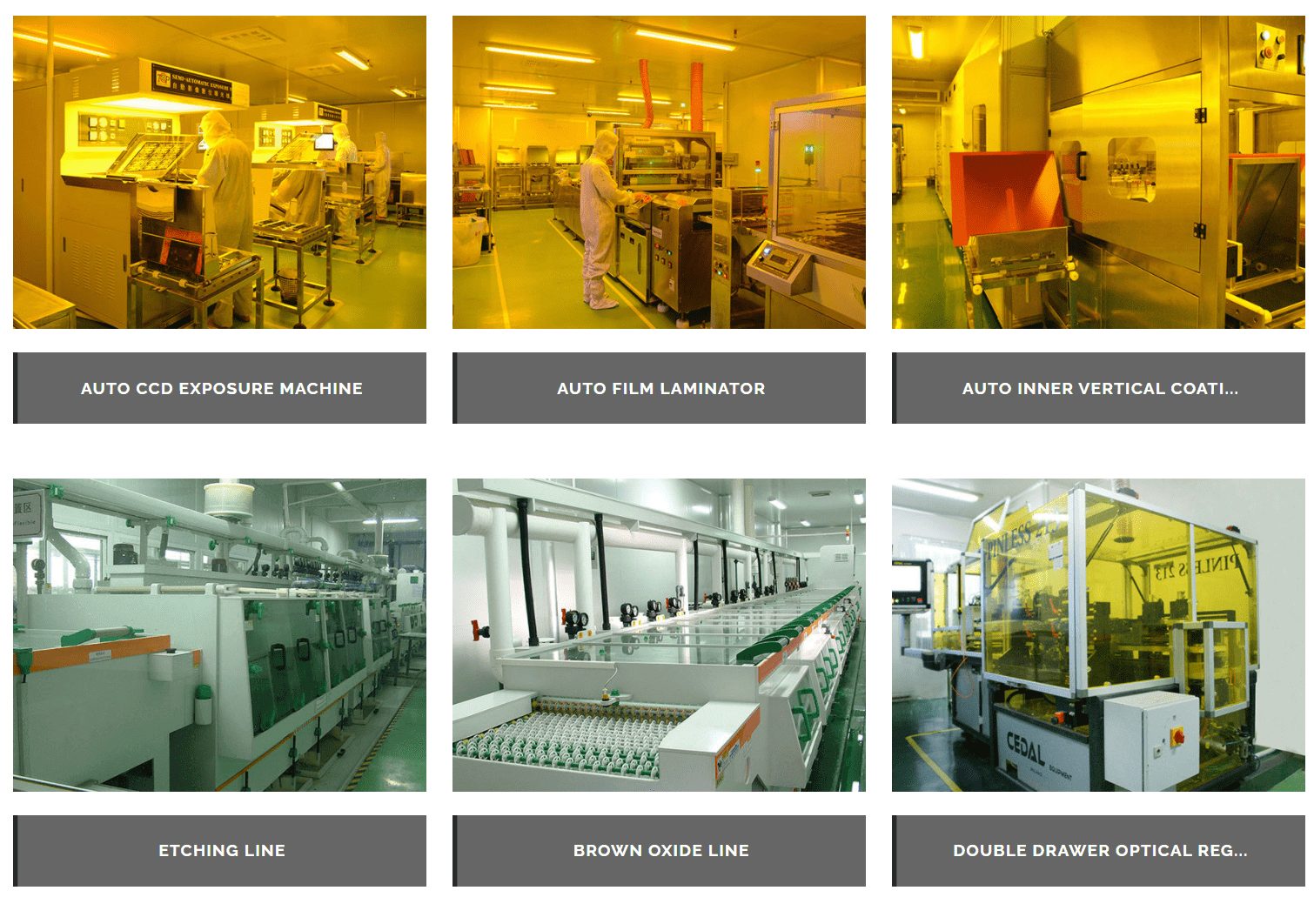

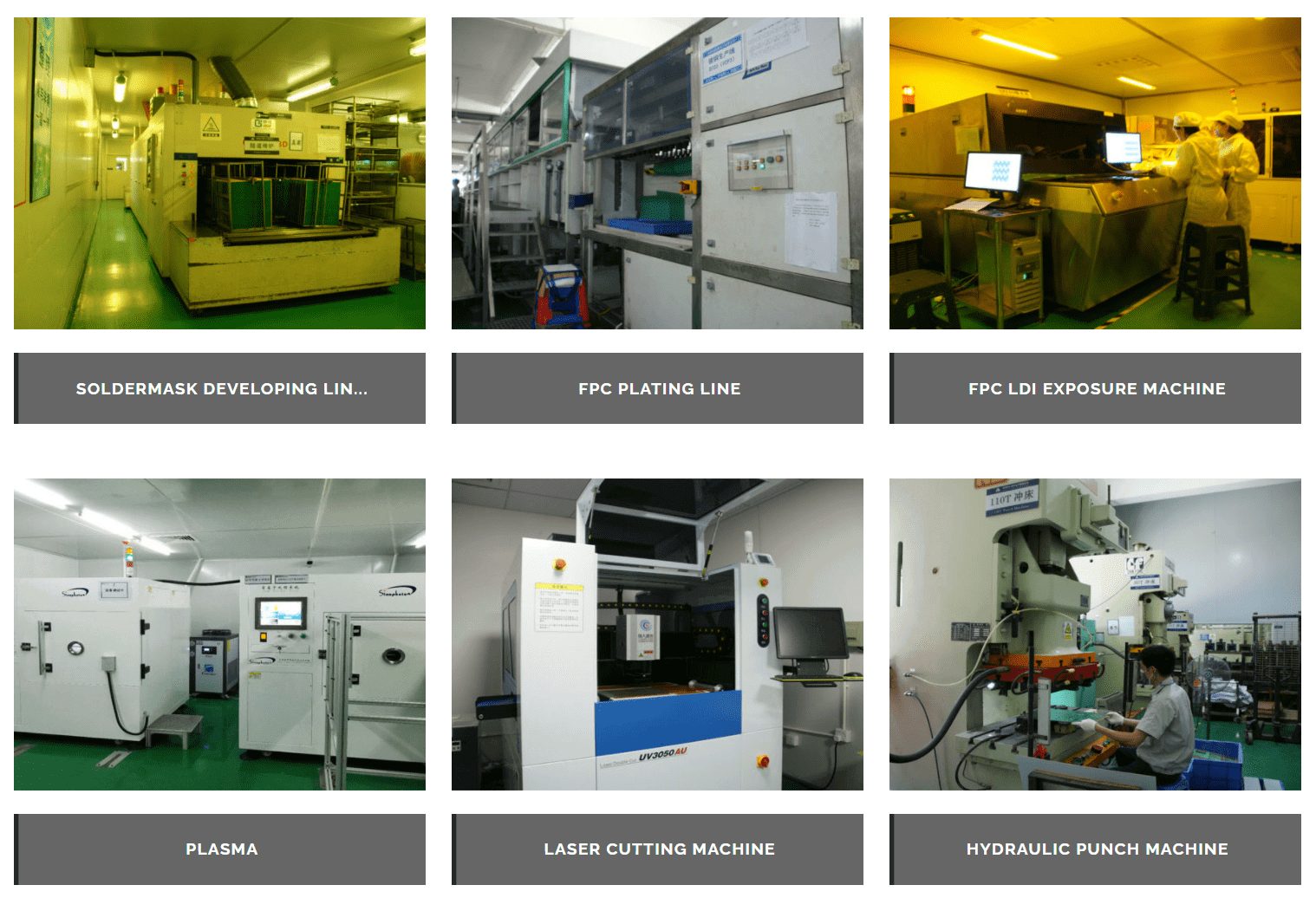

We utilize high-precision imaging systems and etching equipment to create the intricate patterns on each PCB layer. Our exposure units ensure accurate transfer of circuit designs, while our etching machines provide clean, consistent results. - Lamination and Pressing

Our hydraulic lamination presses apply uniform pressure and heat, fusing multiple layers into a solid board. This equipment is crucial for producing multi-layer PCBs with excellent layer-to-layer adhesion. - Drilling and Plating

Our computer-controlled drilling machines create precise holes for vias and component mounting. Following this, our electroless and electrolytic plating lines ensure proper connectivity between layers. - Solder Mask and Silkscreen

We employ advanced solder mask coating equipment and high-resolution silkscreen printers to add protective layers and component markings to the boards. - Testing and Quality Control

Our automated optical inspection (AOI) systems and flying probe testers thoroughly examine each board for defects, ensuring only the highest quality PCBs leave our facility.

Our investment in advanced PCB manufacturing equipment translates directly into superior quality, precision, and reliability for your electronic projects. Whether you need rigid, flex, or rigid-flex PCBs, XPCB Limited has the technology and expertise to bring your designs to life.

Experience the XPCB difference – where innovation meets precision in printed circuit board manufacturing.