Professional PCB Assembly Service

At XPCB, we specialize in delivering high-quality PCB assembly services that meet the diverse needs of our clients across various industries. Our years of experience have established us as a reliable partner in the PCB assembly manufacturing sector.

We offer a comprehensive, one-stop service that covers all aspects of PCB production:

- PCB fabrication

- Component procurement

- Final circuit board assembly

Our team of skilled professionals is at the core of our operations:

• Experienced soldering technicians ensure precise assembly

• SMT process engineers optimize production efficiency

• Component procurement specialists source quality parts at competitive prices

Scope of PCB Assembly Service

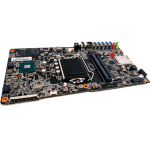

Types of PCB

- Single-Sided

- Double-sided

- IMS (Insulated Metal Substrate)

- Multilayer

- HDI

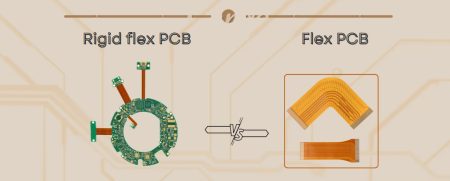

- Flexible

- Semi-Flex

- Rigid-Flex

- Heavy copper

- RF/Microwave

Types of Assembly

- Surface Mount Technology (SMT) Assembly

- Through-Hole Assembly

- Mixed Technology Assembly

- Prototype PCB Assembly

- Low-Volume PCB Assembly

- High-Volume PCB Assembly

- Turnkey PCB Assembly

- Consignment PCB Assembly

- IC Programming

- Conformal Coating

Types of Equipment

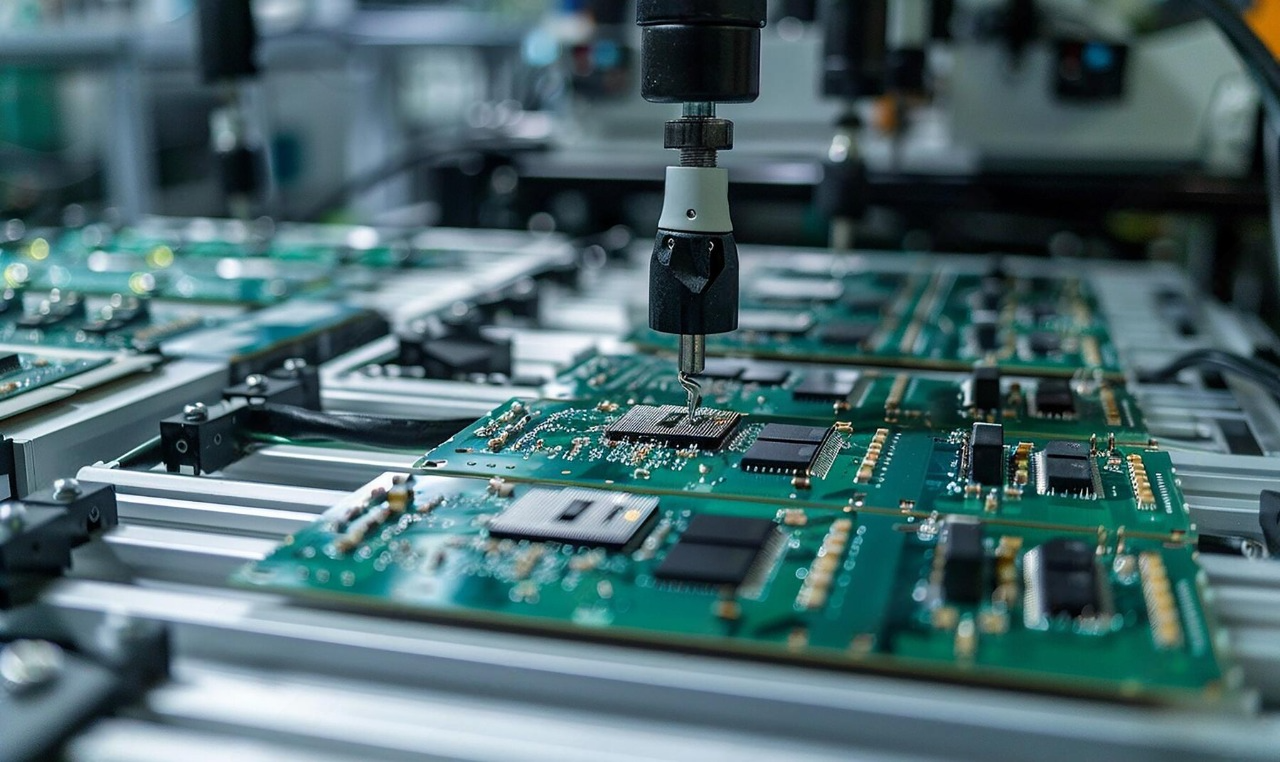

- Pick and Place Machine

- Reflow Oven

- Wave Soldering Machine

- Stencil Printer

- Automated Optical Inspection (AOI) System

- X-ray Inspection System

- Component Tape and Reel Feeder

- Selective Soldering Machine

- Flying Probe Tester

- Conformal Coating Machine

Get a Free Quote

Simplify your PCB assembly process and maximize efficiency with XPCB's state-of-the-art facilities and experienced team

Click Here

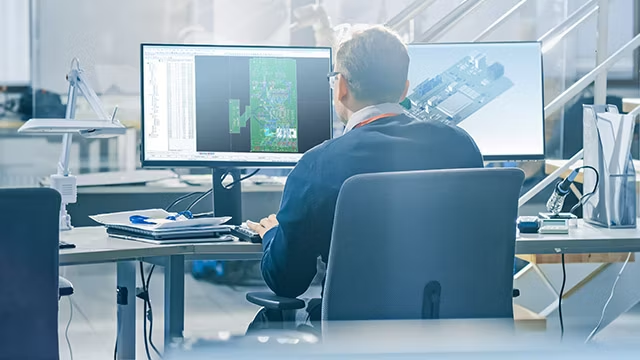

At XPCB, we understand the importance of getting your printed circuit board (PCB) design validated quickly. That’s why we offer industry-leading quick-turn prototyping services to help you accelerate your product development timeline.

Our experienced engineering team works closely with you to optimize your PCB design, taking into account factors such as component placement, signal integrity, and thermal management. We provide design for manufacturability (DFM) guidance to ensure your PCB is ready for efficient and reliable assembly.

Once the design is finalized, we can deliver high-quality PCB prototypes in as little as 3-5 business days. Our state-of-the-art fabrication facilities are equipped with the latest technology, enabling us to rapidly produce prototypes that faithfully represent the final product.

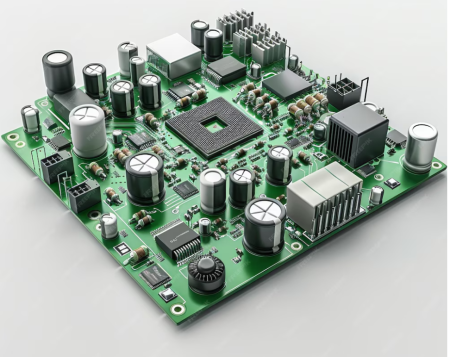

XPCB offers a comprehensive mass PCB manufacturing service for high-volume production runs. We specialize in delivering high-quality, reliable PCBs at competitive prices, with a focus on:

- Expertise: Our experienced team has a deep understanding of PCB design and manufacturing, ensuring your project meets the highest standards.

- Efficiency: We utilize advanced equipment and streamlined processes to deliver your PCBs quickly and efficiently.

- Quality: We adhere to stringent quality control measures throughout the manufacturing process, guaranteeing consistent and reliable results.

- Customization: We offer a wide range of customization options to meet your specific needs, including materials, finishes, and testing requirements.

- Competitive Pricing: We provide competitive pricing without compromising on quality, ensuring you get the best value for your investment.

XPCB offers a comprehensive component sourcing service for turnkey PCBA orders. We take care of everything from sourcing the components to assembling and testing your finished PCBs, so you can focus on your core business.

Benefits of using XPCB’s component sourcing service:

- Save time and money: Our experienced team can source the components you need quickly and efficiently, saving you time and money.

- Reduce your risk: We ensure that all components meet your specifications and are of the highest quality.

- Simplify your supply chain: We handle all aspects of component sourcing and logistics, so you can focus on your core business.

- Get a complete turnkey solution: We take care of everything from component sourcing to PCB assembly and testing, providing you with a complete turnkey solution.

XPCB offers a state-of-the-art SMT assembly service for high-volume production runs. We utilize the latest technology and equipment to deliver high-quality, reliable PCB assemblies quickly and efficiently.

Our SMT assembly service includes:

- High-precision placement: We use advanced pick-and-place machines to ensure accurate and reliable component placement.

- Automated soldering: Our automated soldering processes guarantee consistent and reliable solder joints.

- Quality control: We perform rigorous quality control inspections throughout the assembly process to ensure that your PCBs meet the highest standards.

- Testing: We offer a variety of testing services to ensure that your PCBs are fully functional.

- Turnkey solutions: We can handle all aspects of your SMT assembly needs, from component sourcing to final testing.

XPCB offers a comprehensive through-hole assembly service for high-quality, reliable PCB assemblies. We utilize experienced technicians and state-of-the-art equipment to ensure that your through-hole components are assembled accurately and efficiently.

Our through-hole assembly service includes:

- Manual component placement: Our experienced technicians carefully place each through-hole component onto your PCB.

- Wave soldering: We use a state-of-the-art wave soldering process to create reliable and consistent solder joints.

- Quality control: We perform rigorous quality control inspections throughout the assembly process to ensure that your PCBs meet the highest standards.

- Testing: We offer a variety of testing services to ensure that your PCBs are fully functional.

- Turnkey solutions: We can handle all aspects of your through-hole assembly needs, from component sourcing to final testing.

XPCB offers a comprehensive conformal coating service to protect your PCBs from harsh environments and extend their lifespan. We utilize high-quality materials and experienced technicians to ensure that your PCBs are coated evenly and effectively.

Benefits of using XPCB’s conformal coating service:

- Protection from harsh environments: Our conformal coatings protect your PCBs from moisture, dust, chemicals, and other contaminants.

- Extended lifespan: Conformal coating can help to extend the lifespan of your PCBs by protecting them from damage.

- Improved reliability: Conformal coating can help to improve the reliability of your PCBs by preventing short circuits and other electrical failures.

- Turnkey solutions: We can handle all aspects of your conformal coating needs, saving you time and money.

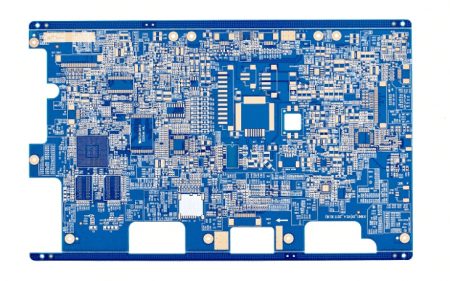

Multilayer PCB Assembly and HDI PCB Manufacturing for High-Tech Solutions

The rapidly evolving world of technology demands innovative and high-performing electronic solutions. Multilayer Printed Circuit Boards (PCBs) and High-Density Interconnect (HDI) PCBs have become pivotal in

Streamline Your PCB Production with XPCB’s Turnkey PCBA Services

In today’s competitive electronics industry, efficiency and reliability are paramount. XPCB’s turnkey Printed Circuit Board Assembly (PCBA) services offer a one-stop solution to streamline your production

Comprehensive Turnkey PCBA Services: From BOM to SMT Assembly

In today’s fast-evolving electronics industry, speed, quality, and cost-effectiveness are critical for staying ahead of the competition. Turnkey PCB Assembly (PCBA) services address these demands by

XPCB Limited: Multilayer Rigid PCB and HDI PCB Experts

In the ever-evolving world of electronics, PCBs (Printed Circuit Boards) are the backbone of innovation, powering devices from smartphones to advanced medical systems. Among the diverse

XPCB Limited: Expertise in HDI PCB Manufacture and Complete SMT Services

In the fast-paced world of electronics manufacturing, delivering compact, efficient, and high-performance products is a challenge that demands innovative solutions. XPCB Limited rises to this challenge

From Flex PCB to Rigid-Flex PCB: Comprehensive PCB Solutions for Every Industry

In the realm of modern electronics, printed circuit boards (PCBs) form the backbone of virtually every device. As industries demand smarter, more compact, and robust solutions,