- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

If you want to do it for a long time in the industry, excellent quality is the king, and the PCB industry is no exception. It is necessary for PCB tests. There are several common methods for automotive PCB testing.

The most traditional test method, the inspector uses a magnifying glass or a calibrated microscope to check to determine whether the circuit board is unqualified, and the advantages: no test fixture cost; Disadvantages: long test time, discontinuous defect detection, difficult data collection, etc. With the continuous increase of PCB production, the wire spacing and component volume on the PCB are reduced, and this method can only use simple single-sided and complex double-sided multi-layer boards, and do not use to find problems.

When the production line is not accurate, the PCB board is detected, and it is best to do a test after each process, which helps to provide PCB yield and electrical performance detection: find out manufacturing defects and test analog, digital and mixed-signal components to ensure that they meet the specifications, and have several test methods such as bed-of-needle tester and flying probe tester.

Based on the principle of optics, combined with image analysis and other technologies, the problems encountered in production are detected and handled.

Use laser beam scanning to manufacture PCB board and collect all measurement data.

Participate in the test work as soon as possible on the production line, communicate with the business department in a timely manner to understand customer needs, prepare for the test, and know the PCB friends know that the PCB test cycle is short, if the developer delays the time in the early stage.

In order not to affect the progress of the project, it is more tense to leave the PCB processing plant to produce, if the tester does not communicate with the business department / engineering department in advance / When the production department communicates, it will not be able to truly understand the product attributes, and the test data will not be sufficient, which will easily cause long test time and low efficiency.

Create a communication group of the quality department, before the order is put into production, the person in charge of the quality department should make a detailed test basic requirements table for each PCB, and a reasonable and detailed test plan can improve the online test staff to understand the unique requirements of each PCB in a timely manner, so as not to blind and purposeless testing.

The quality manager should do a good job in the review of test documents in a timely manner, try to use fewer test cases and find more bugs, which is undoubtedly a way to quickly improve the effect of the test efficiency, and improve the acceptance standard of the quality test, and reduce the number of repeated test boards.

Internal training should be carried out in a timely manner for testers, so that each employee can grasp the latest standards of various industries in a timely manner, and secondly, the test work is a job with high communication requirements, usually need to communicate with project managers, developers, product managers, colleagues in the business department, and customers.

And need to take the initiative to communicate with the engineering department, production department, and customers in a timely manner to understand the latest situation of customer requirements or changes. The more precise it is, the smoother it will be when it comes to testing work.

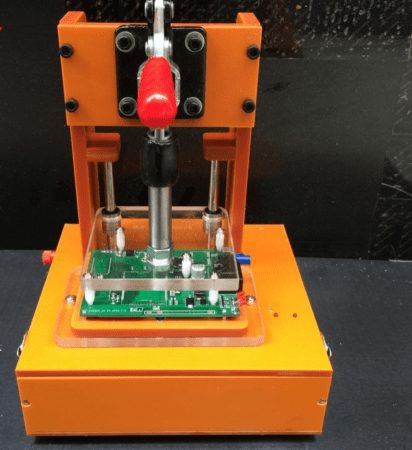

The test rack used in each industry is the same, and the test frame used by PCB factories refers to a detection tool used to test whether the PCB board has problems such as open circuits and short circuits, which is called “PCB test frame”. Almost all PCB will be tested, except for some particularly simple single-sided panels, it is possible to choose visual inspection, usually there are two ways to test PCB, flying probe test and test rack, flying probe test is only suitable for small batch samples, for batch board 98% Customers will choose to open the test frame.

In addition to the high efficiency of the test frame, the cost of the test frame is only charged once, not like the flying probe test will be charged every time, most of the other PCB factories, the cost of the test frame can be returned, but some set standards for a single model of 30,000 or 50,000 can be refunded to the cost of the test frame, of course, each set standard is somewhat different.

The materials needed to make PCB test racks are: acrylic sheets, positioning columns, thimbles, cards, leads, etc. The production of fixtures should be based on the actual situation to select appropriate materials, which can greatly reduce the production cost, while the general reusable base night can reduce costs, and make the fixture production standardized and convenient to make, improve the quality of the fixture, the selection of test needles and related materials in the test frame is very important to test the quality and cost of the fixture.

Discover a World of Possibilities with XPCB Limited

At XPCB Limited, we’re here to help you explore new horizons. Our advanced PCB manufacturing, rapid prototyping, and turnkey PCBA solutions make it easy for you to turn your ideas into reality. Trust us to deliver excellence and reliability every step of the way. Join us and experience the power of innovation with XPCB Limited by your side.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve