- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

Menu

1. Degradation of electrical performance: Poor PCB surface of the circuit board will cause the electrical performance of the circuit board to deteriorate, such as signal distortion, increased noise, interference, etc.

2. Signal interference: Poor surface of the circuit board will cause signal interference of the circuit board, which will cause the circuit board to lose stability and cause equipment failure or damage.

3. Poor soldering: Poor surface of the PCB will lead to poor soldering, such as unstable soldering joints, soldering position deviation, etc., which will affect the service life and reliability of the circuit board.

4. Increased cost: Defective circuit board surfaces need to be reworked or remanufactured, which will increase production costs and manufacturing cycles.

5. Safety hazards: Poor PCB surface may lead to problems such as short circuits and overcurrents of the circuit board, which pose a threat to the safety of equipment and personnel.

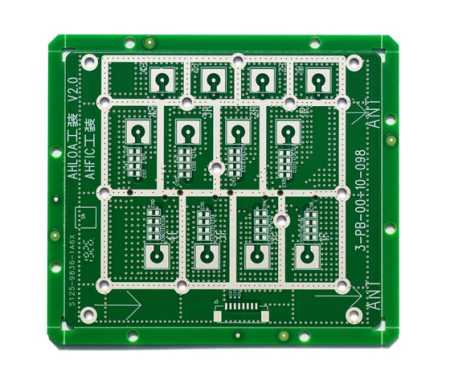

Image 1: The Analysis of the PCB Surface Residues

For some thin substrates (usually less than 0.8mm), due to the poor rigidity of the substrate, in the production and processing of the substrate. It may not be possible to effectively remove the protective layer that has undergone special treatment to prevent the copper foil from oxidizing on the PCB surface. Although the layer is thin and the brush is easier to remove, it is difficult to carry out chemical treatment. So in the production process of the circuit board, it is necessary to pay attention to the control during the processing process.

This can avoid the problem of blistering on the board due to poor adhesion, between the copper foil of the substrate and the electroless copper. When the thin inner layer turns black, it can lead to blackening and browning, poor, uneven color, partial black-browning, and other problems.

Poor surface treatment is caused by oil stains or other liquids contaminated with dust during the machining (drilling, laminating, milling, etc.) of the substrate surface.

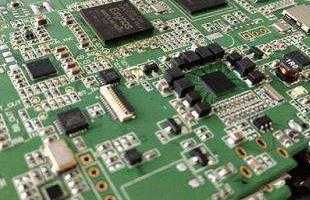

Image 2: Disadvantages of PCB Surface Treatment Process

Poor copper immersion: the pressure of the brush plate will not cause the substrate to leak, the roughness of the orifice copper will be increased when the copper is immersed. So the copper foil at this position is easy to over-roughen in the micro-etching process, and there will be quality hidden dangers. Attention should be paid to strengthening the control of the brushing process, and the parameters of the brushing process can be adjusted to the best state through the wear mark test and water film test.

Water washing problem: Since the electroplating treatment of immersion copper must go through a lot of chemical treatment. There are many kinds of acids, alkalis, organic, and other pharmaceutical solvents, and the PCB surface cannot be cleaned with water, especially.

The degreaser used for the adjustment of sinking copper will not only cause cross-contamination, but also lead to poor local treatment or poor treatment effect of the board surface, uneven defects, and some bonding problems. This should be paid to strengthening the control of washing, mainly including the flow of washing water, water quality, and washing time, as well as the control of panel dripping time. Especially in winter, when the temperature is low, the washing effect will be greatly reduced, and more attention should be paid to the control of washing.

Image 3: The Source of PCBA Surface Residues

Discover a World of Possibilities with XPCB Limited

At XPCB Limited, we’re here to help you explore new horizons. Our advanced PCB manufacturing, rapid prototyping, and turnkey PCBA solutions make it easy for you to turn your ideas into reality. Trust us to deliver excellence and reliability every step of the way. Join us and experience the power of innovation with XPCB Limited by your side.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2023 - XPCB Limited All Right Reserve