- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

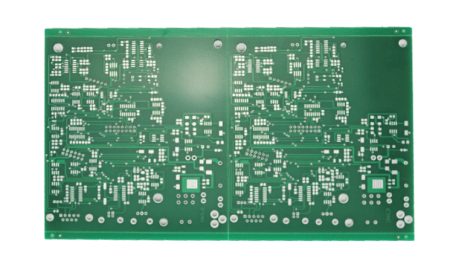

PCB Immersion gold and gold plating are surface treatment techniques used to improve the durability and performance of printed circuit boards (PCBs). These processes involve the application of a thin gold coating to the PCB surface, offering several advantages over traditional PCB finishes.

The so-called PCB immersion gold process refers to the formation of a layer of plating through the method of chemical redox reaction, which is generally thicker, and is a kind of electroless nickel gold layer deposition method, which can achieve a thicker gold layer.

PCB immersion gold, also known as electroless immersion gold (ENIG), is a chemical deposition process used to apply a thin layer of gold to the PCB surface. The process involves immersing the PCB in a chemical bath that contains a complexing agent and a reducing agent.

As the PCB passes through the bath, the gold ions and the complexing agent react, resulting in the reduction of the gold ions from Au3+ to Au0. The gold ions adhere to the PCB surface, forming a uniform gold film.

PCB gold plating is also known as “electroplating gold”, “electroplating nickel gold plate”, “electrolytic gold”, “electric gold” and “electronickel gold plate”, gold plating is divided into soft gold and hard gold, hard gold is used for gold finger circuit board products, the principle is to dissolve nickel and gold (commonly known as gold salt) in chemical solutions, dip the circuit board in the electroplating cylinder and turn on the current to generate nickel gold plating on the copper foil surface of the circuit board, electronickel gold because of the high hardness of the plating, the more resistant to wear.

1. The thickness of immersion gold is thicker than that of gold plating, and the surface of immersion gold is golden yellow than that of gold plating, and immersion gold can make customers more satisfied from the plate surface.

2. The crystal structure formed by immersion gold and gold plating is different, immersion gold is easier to weld than gold plating, and it is not easy to have poor welding in the welding process.

3. Compared with gold plating, immersion gold has a denser crystal structure and is not easy to oxidize.

4.As the wiring of precision products becomes more and more precise, some line widths and spacing have been as low as 3mil, which is easy to produce gold wire short circuit for the gold plating process of high-precision plates. The immersion gold plate only has nickel gold on the pad, and there will be no gold wire short circuit. Moreover, the solder mask on the line is more firmly combined with the copper layer, and the project has any negative impact on the intermittent moment when making data compensation.

5. Compared with the high-frequency board with high requirements, the flatness of the immersion gold plate should be good, and there will be no black pad phenomenon after assembly. More importantly, the flatness and standby life of immersion gold plate are stronger than that of gold plated plate.

In conclusion, PCB immersion gold and gold plating are two surface treatment techniques commonly used to improve the durability and performance of PCBs. Both processes offer several advantages, including enhanced corrosion resistance, good electrical conductivity, and solderability. The choice of process depends on the specific application requirements and the desired finish.

Discover a World of Possibilities with XPCB Limited

At XPCB Limited, we’re here to help you explore new horizons. Our advanced PCB manufacturing, rapid prototyping, and turnkey PCBA solutions make it easy for you to turn your ideas into reality. Trust us to deliver excellence and reliability every step of the way. Join us and experience the power of innovation with XPCB Limited by your side.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

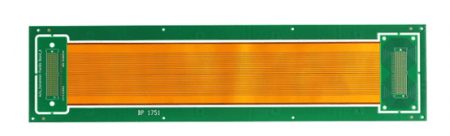

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve