- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

High-Density Interconnect (HDI) PCBs have revolutionized modern electronics, enabling the design of compact, high-performance devices. Among the critical features that distinguish HDI PCBs are blind vias and buried vias. These specialized interconnects play a pivotal role in enhancing the performance, reliability, and manufacturability of HDI PCBs. Understanding their impact is essential for optimizing HDI PCB designs for demanding applications.

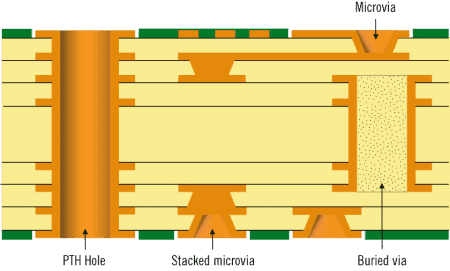

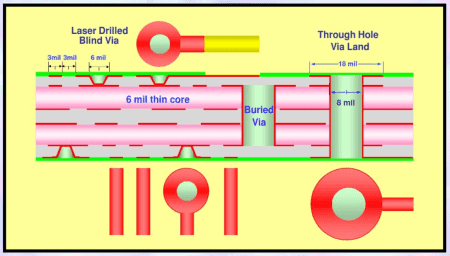

Blind vias are connections that link an outer layer of a PCB to one or more inner layers but do not pass through the entire board. These vias are typically used in HDI designs to save space on densely packed outer layers.

Buried vias, on the other hand, are entirely encapsulated within the inner layers of the PCB and do not extend to the outer layers. These vias are crucial for connecting internal layers without interfering with the surface routing.

Both blind and buried vias enable intricate layer-to-layer connections while maximizing the available surface area for components and traces. This capability is particularly important for HDI PCBs, which are commonly used in mobile devices, wearable electronics, automotive systems, and advanced medical devices.

Despite their advantages, blind and buried vias introduce certain challenges:

Blind and buried vias are indispensable tools for optimizing the performance of HDI PCBs. They enable high-density routing, enhance electrical and thermal performance, and support the miniaturization of electronic devices. While they introduce certain challenges, careful design and collaboration with manufacturers can mitigate these issues, unlocking the full potential of HDI PCB technology. By leveraging the advantages of blind and buried vias, engineers can meet the ever-increasing demands of modern electronic applications.

Simplify and Streamline Your PCB Projects with XPCB’s Advanced Manufacturing

Say goodbye to complex PCB processes and hello to simplicity with XPCB Limited. Our advanced PCB manufacturing capabilities allow us to deliver high-quality boards tailored to your unique needs. Whether it’s a simple prototype or a complex multilayer PCB, we streamline the entire process to save you time and resources. Experience effortless PCB manufacturing with XPCB Limited.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

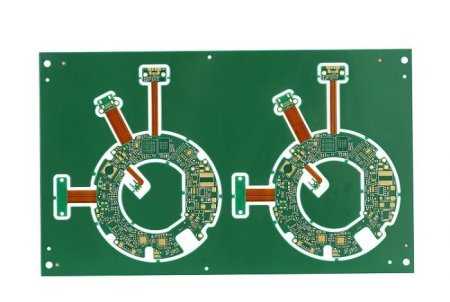

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve