- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

In today’s tech-driven world, innovation is synonymous with adaptability, efficiency, and performance. Flexible printed circuit boards (Flex PCBs) have emerged as a pivotal component in modern electronics, enabling groundbreaking designs and applications across industries. In this blog, we’ll explore the insights of electronics experts on how Flex PCBs are shaping the future of technology, their unique benefits, and their transformative applications.

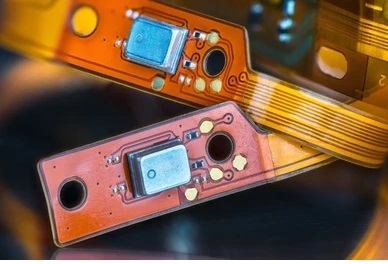

Flex PCBs, also known as flexible circuits, are thin, lightweight, and bendable circuit boards. Unlike traditional rigid PCBs, they can be twisted, folded, and shaped to fit into compact or irregular spaces. This unique adaptability has positioned Flex PCBs as a game-changer in industries that prioritize miniaturization, reliability, and durability.

As devices become smarter, smaller, and more interconnected, the demand for Flex PCBs has surged. According to industry experts, the global Flex PCB market is poised for significant growth, driven by advancements in IoT (Internet of Things), wearables, medical devices, and automotive technologies.

Despite their numerous advantages, Flex PCBs come with challenges that experts are working to address:

Flex PCBs are redefining the possibilities in electronics design and manufacturing, enabling innovations that were once unimaginable. Their adaptability, reliability, and performance are unlocking new frontiers in industries ranging from healthcare and automotive to consumer electronics and beyond.

As technology continues to advance, the insights and expertise of electronics professionals will be vital in harnessing the full potential of Flex PCBs. By overcoming challenges and embracing new opportunities, Flex PCBs will remain at the forefront of tech innovation, driving progress in an increasingly connected world.

Make Your PCB Dreams a Reality with XPCB Limited

XPCB Limited is your go-to partner for turning your PCB dreams into reality. Our streamlined PCB manufacturing process, combined with quick-turnaround prototyping and turnkey PCBA services, ensures that your projects come to life with ease. Trust in our expertise and dedication to quality as we help you achieve your PCB goals. Join us and experience the difference with XPCB Limited.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve