- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

Menu

Printed circuit boards have a particularity, that is, each PCB is customized. When we design a project, we are more concerned about layout and wiring, etc., and often ignore which design factors will add additional board manufacturers. Therefore, usually, the original data of the circuit board PCB needs to be sent to the manufacturer to get the correct quotation. Then, what are the design factors of the PCB board that will affect the manufacturing price?

The above are the design factors that affect the price of PCB. It is not difficult to find the biggest factors affecting the price of PCB circuit boards, namely the complexity of PCB circuit board proofing depends on the number of layers and vias because this defines the change of layers at which vias start and stop, and more lamination and drilling steps are required in the circuit board manufacturing process.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

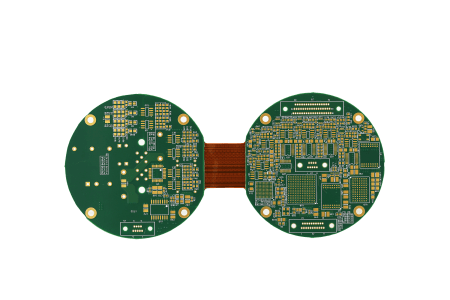

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2023 - XPCB Limited All Right Reserve