- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

Menu

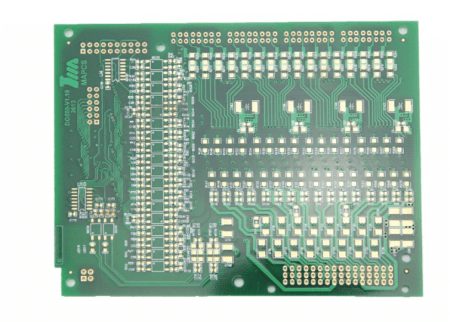

The automatic soldering machine provides convenience for the soldering tin, but there are often problems in the production process, which will affect the quality of the soldering tin. In order to improve the testing effect, some technical processing should be done on the repaired board before the online function test of the PCB circuit board to minimize the impact of various interferences on the test process. The specific measures are as follows:

1. Preparation before the test.

Short-circuit the crystal oscillator. Note that for the four-pin crystal oscillator, you must find out which two pins are the signal output pins. You can short-circuit these two pins. Remember that the other two pins are the power pins under normal circumstances. Do not short-circuit! For large-capacity electrolysis, the capacitor should also be soldered to make it open. Because the charging and discharging of large-capacity capacitors will also bring interference.

2. Use the elimination method to test the PCB circuit board of the device.

During the online test or comparison test of the device, if the device passes the test or is relatively normal, please directly confirm the test result and record it. If the test fails or is out of tolerance, it can be tested again. If it still fails, you can confirm the test result first. In this way, the test continues until the device on the board is tested or compared. Then deal with those devices that fail the test or are out of tolerance.

For devices that cannot be tested online, some test instruments also provide a less formal but more practical processing method. Because the power supply of this test instrument to the circuit board can also be applied to the corresponding power supply and the device through the test clip. If the power pin of the device is cut on the ground pin, the device will be separated from the circuit board power supply system.

At this time, perform online functional testing of the device. Since other components on the PCB circuit board will not be energized to eliminate the interference effect, the actual test effect at this time will be equivalent to the “quasi-offline test”. Accuracy rate will be very greatly improved.

XPCB Limited is a manufacturer specializing in the production of high-precision double-sided, multi-layer and impedance, blind buried vias, and thick copper circuit boards. The products cover HDI, thick copper, backplanes, rigid-flex combined, buried capacitance and buried resistance, Golden Finger and other types of circuit boards, which can meet the needs of customers for various products.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2023 - XPCB Limited All Right Reserve