- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

Menu

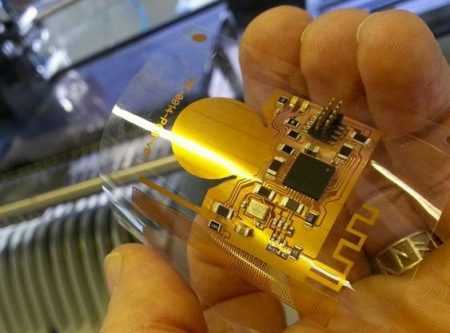

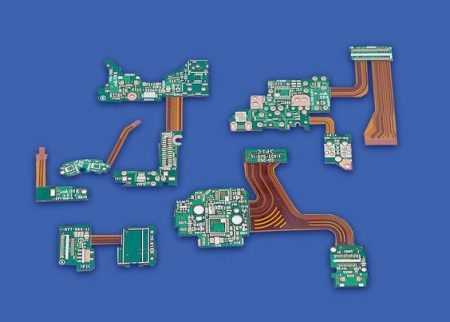

At present, there are four kinds of flexible circuit: single side, double side, multi-layer flexible board and rigid-flex PCB.

The best performance-price ratio can be achieved by evaluating the convenience and total cost of the inline design.

If the circuit design is relatively simple, the total volume is not large, and the space is suitable, the traditional interconnect mode is mostly much cheaper. Flexible circuits are a good design choice if the circuit is complex, handles many signals, or has special electrical or mechanical performance requirements. Flexible assembly is most economical when the size and performance of the application exceeds the capacity of the rigid circuit. A 12MIL pad with 5miL through-hole and a 3mil line and spacing flexible circuit can be made on a single film. Therefore, it is more reliable to mount the chip directly on the film. Because it does not contain flame retardants that may be a source of contamination from the ion drill. These films may be protective and solidify at higher temperatures, resulting in higher vitrification temperatures. The reason why flexible materials save cost compared with rigid materials is that connectors are not used.

The high cost of raw materials is the main reason for the high price of flexible circuits. The price of raw materials varies greatly. The cost of raw materials for the lowest polyester flexible circuit is 1.5 times as much as that for the rigid circuit. High-performance polyimide flexible circuits are up to four times higher. At the same time, the flexibility of the material makes it difficult to be processed automatically in the manufacturing process, which leads to the decrease of the output. Defects are easy to occur in the final assembly process, such as stripping of flexible accessories and line fracture. This is more likely to happen when the design is not suitable for the application. Under the high stress caused by bending or forming, it is often necessary to choose reinforcing materials or reinforcing materials. Despite its high cost of raw materials and troublesome, foldable, flexible and multi-layer plywood functions will reduce the size of the overall component, resulting in a reduction in the materials used, resulting in a reduction in the total assembly cost.

Flexible circuit industry is in small scale but rapid development. Polymer thick film method is an efficient and low-cost production process. The process on the cheap flexible substrate, selective screen-printing conductive polymer ink. Its representative flexible substrate is PET. The polymer thick film method conductor includes the screen-printing metal packing or the toner packing. The polymer thick film method itself is clean, using lead-free SMT adhesives that do not need to be etched. Due to the addition process and low base material cost, the polymer thick film circuit is 1/10 of the price of copper polyimide film circuit. It’s 1/2 to 1/3 of the price of the rigid circuit board. The polymer thick film method is especially suitable for the control panel of equipment. For mobile phones and other portable products, the polymer thick film method is suitable for converting components, switches and lighting devices on the printed circuit board into polymer thick film circuits. It saves costs and reduces energy consumption.

Generally speaking, flexible circuits do cost more and cost more than rigid circuits. When flexible PCB are manufactured, in many cases they have to face the fact that many parameters are beyond the tolerance range. The difficulty in making flex PCB lies in the flexibility of materials.

Despite the above cost factors, the price of flexible assembly is falling, becoming close to that of traditional rigid circuits. The main reasons are the introduction of newer materials, the improvement of production process and the change of structure. The current structure makes the product more thermally stable with few material mismatches. Some newer materials, with thinner copper layers, can produce more precise lines, making components lighter and better suited to small Spaces. In the past, copper foil was adhered to a medium coated with adhesive by rolling process. Now, copper foil can be generated directly on the medium without the use of adhesive. These techniques can produce layers of copper several microns thick and precise lines 31.1 or narrower in width. The flexible circuit has flame retardant property after removing some adhesives. This will both speed up the UL certification process and further reduce costs. Solder masks and other surface coatings for flexible circuit boards further reduce the cost of flexible assembly.

In the coming years, smaller, more complex and more expensive flexible circuits will require more innovative methods of assembly and the addition of hybrid flexible circuits. The challenge for the flexible circuit industry is to take advantage of its technological advantages to keep pace with computing, telecommunications, consumer demand, and an active market. In addition, flexible circuit will play an important role in lead-free operation.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2023 - XPCB Limited All Right Reserve