- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

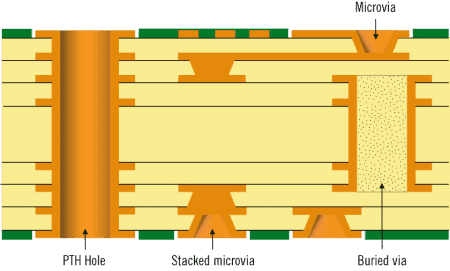

High-Density Interconnect (HDI) technology has become a cornerstone of modern printed circuit board (PCB) manufacturing. With the rise in demand for compact, high-performance electronics, the integration of HDI technology, combined with blind-via and buried-via designs, plays a pivotal role in enabling advanced, complex PCB architectures. This article delves into the applications and advantages of these technologies in complex PCB manufacturing, shedding light on their transformative impact.

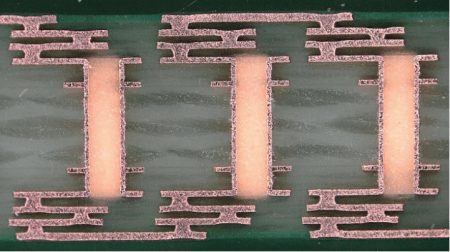

HDI PCBs are characterized by their higher wiring density per unit area compared to traditional PCBs. They achieve this by utilizing smaller vias, finer lines and spaces, and more precise component placement. HDI technology supports advanced features like:

These design elements allow for a reduction in board size while maintaining or even increasing functionality, making HDI an essential choice for miniaturized devices like smartphones, wearables, and IoT devices.

Blind and buried vias are critical in achieving the compactness and high functionality of HDI PCBs. Their unique configurations offer several advantages:

The integration of HDI technology and blind/buried vias unlocks numerous possibilities in complex PCB manufacturing. Key applications include:

When implemented effectively, HDI technology with blind and buried vias offers several manufacturing advantages:

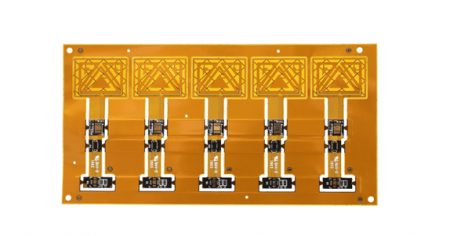

4 layer Flex Circuit with HDI

While HDI and via technologies bring numerous benefits, they also present challenges, such as:

To address these challenges, manufacturers adopt advanced techniques such as laser drilling for microvias, high-quality materials for improved durability, and stringent quality control processes to ensure reliability.

The integration of HDI technology with blind and buried vias has revolutionized complex PCB manufacturing. By enabling compact, high-performance designs, these technologies are driving innovation across industries, from consumer electronics to automotive and medical devices. As the demand for miniaturized, high-functionality products continues to grow, the role of HDI technology in PCB manufacturing will only become more significant. Manufacturers who invest in mastering these advanced techniques are poised to lead the way in next-generation electronic design and production.

XPCB Limited: Advanced PCB Manufacturing to Simplify Your Journey

Navigating the complexities of PCB production has never been easier. XPCB Limited combines advanced PCB manufacturing technology with streamlined processes to offer solutions that meet your exact requirements. From prototypes to mass production, we are committed to quality, speed, and affordability. Trust XPCB Limited to make your PCB journey simple and successful.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve