- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

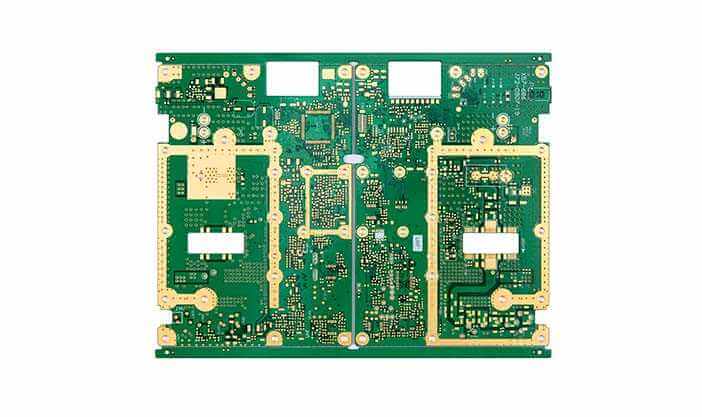

Electronic manufacturing printed circuit board (hereafter referred to as PCB) products have been in commercial use since 1948, began to rise in the 1950s and widely used. The traditional PCB industry is a labor-intensive industry with a lower technology intensity than the semiconductor industry. Since the beginning of the 21st century, the semiconductor industry has been gradually transferred from the United States and Japan to Taiwan and mainland China. Up to now, China has become a global influential PCB producer, PCB output accounted for more than 60% of the world.

Today’s advances in medical science are entirely due to the rapid growth of the electronics industry. Most medical devices, such as pH meters, heart rate sensors, temperature measurements, Electrocardiograms/electroencephalograms, MRI machines, X-rays, CT scans, blood pressure machines, blood glucose level measurement devices, incubators, microbial devices, and many others are individually PCB-based. These PCBS are usually compact and have small shape factors. Denser means smaller SMT components are placed in smaller PCB sizes. These medical devices are smaller, easier to carry, lighter and easier to operate.

PCBs are also widely used in manufacturing, factories, and imminent factories. These industries have high-power mechanical equipment, which is driven by high-power operating circuits that require high current. To do this, a thick layer of copper is applied to the top layer of the PCB, which, unlike the complex electronic PCB, has a current of up to 100 amperes. This is particularly important in applications such as arc welding, large servomotor drivers, lead-acid battery chargers, military industries, and clothing cotton ambiguates.

In lighting, the world is moving towards energy efficient solutions. These halogen bulbs are now rarely found, but now we see LED lights around and high intensity led. These small led provide high brightness light and are mounted on aluminum – based PCBs. Aluminum has the property of absorbing heat and dissipating it in the air. Therefore, due to high power, these aluminum PCBs are commonly used in LED lamp circuits for medium and high-power LED circuits.

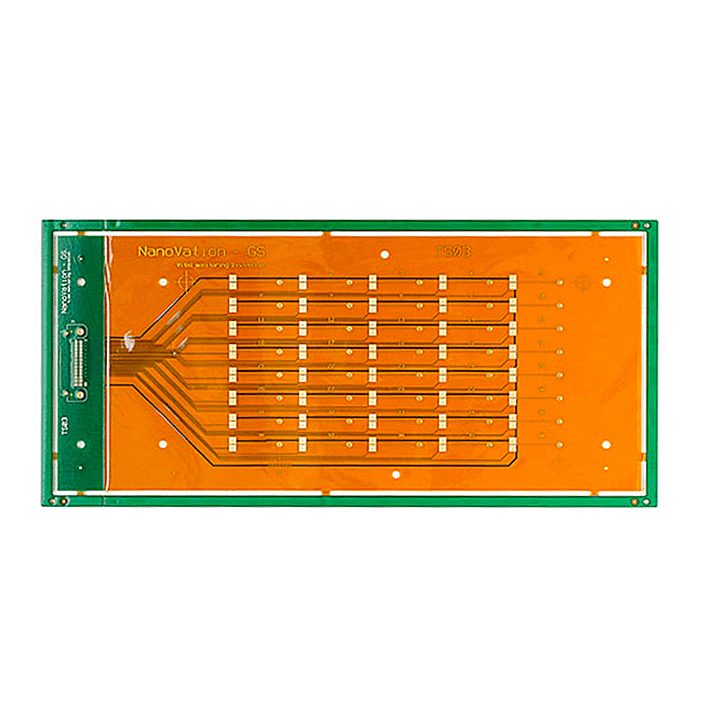

Another application of PCB is in the automotive and aerospace industries. A common factor here is the reverberation produced by moving aircraft or cars. Therefore, in order to satisfy these high-force vibrations, the PCB becomes flexible.

So, use a PCB called a Flex PCB. Flexible PCB can withstand high vibration and light weight, which can reduce the overall weight of the spacecraft. These flexible PCBS can also be adjusted in a narrow space, which is also a big advantage. These flexible PCBS are used as connectors, interfaces, and can be assembled in a compact space such as behind the panel, under the dashboard, etc. A combination of rigid and flexible PCB (rigid-flex PCB) is also used.

In terms of application industry distribution, consumer electronics accounts for the highest proportion, reaching 39%; Computer accounted for 22%; Communication accounts for 14%; Industrial control and medical devices account for 14%; Automobile electronics accounted for 6%; National defense and aerospace accounted for 5%, and aerospace and medical instruments and other fields have very high requirements for PCB precision.

The reason why PCB is so widely used is that it has many unique advantages, which can be summarized as follows.

PCB high density can be developed with the improvement of integrated circuit integration and installation technology.

Through a series of inspection, testing and aging tests, PCB can be guaranteed to work reliably for a long time.

For PCB’s various performance (electrical, physical, chemical, mechanical, etc.) requirements, can be achieved through design standardization, standardization, etc., printed board design, short time, high efficiency.

With modern management, standardization, scale (quantity), automation and other production can be carried out to ensure the consistency of product quality.

A relatively complete test method, test standard, various test equipment and instruments were established to test and identify the PCB product conformity and service life.

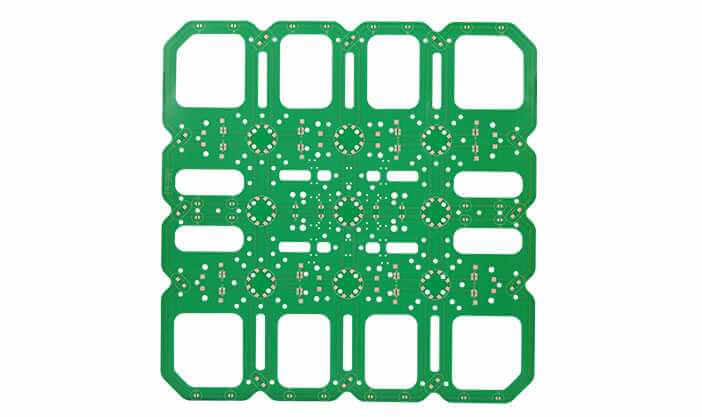

PCB products are not only convenient for standardized assembly of various components, but also for automatic and large-scale production.

At the same time, PCB and various components assembly parts can be assembled into larger parts, systems, even the complete machine.

Since PCB products and component assemblies are designed and manufactured on a standardized scale, they are standardized.

So, once the system failure, can be quickly, convenient, flexible replacement, quickly restore service system work.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve