- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

Menu

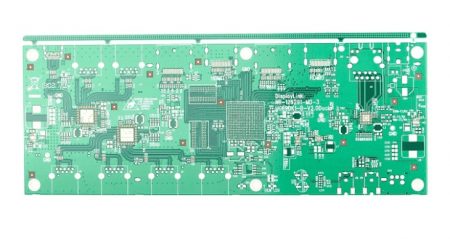

How many problems do you need to pay attention to in the process of the automotive PCB prototype? This chapter makes a detailed analysis of the basic knowledge of automotive PCB proofing, so in the process of automotive PCB proofing, these 8 aspects need to be paid special attention to:

It is not allowed to use a live soldering iron for soldering, to confirm that the soldering iron is not charged, it is best to ground the shell of the soldering iron, and be more careful with the MOS circuit, and it is safer to use a low-voltage circuit iron of 6~8V.

Before inspecting and repairing integrated circuits, it is necessary to familiarize yourself with the functions of the integrated circuits, the internal circuits, the main electrical parameters, the role of each pin, the normal voltage of the pins, the working principle of the circuit composed of waveforms and peripheral components. If the above conditions are met, it will be much easier to analyze and inspect.

When measuring the DC voltage of the integrated circuit pin, a multimeter with an internal resistance greater than 20KΩ/V should be selected, otherwise there will be a large measurement error for some pin voltages.

The power integrated circuit should have good heat dissipation, and it is not allowed to work in a high-power state without a heat sink.

When welding, it is indeed soldered, and the accumulation of solder and porosity are easy to cause virtual soldering. The soldering time is generally not more than 3 seconds, and the power of the soldering iron should be about 25W with internal heating. It is best to use an ohmmeter to measure whether there is a short circuit between the pins to confirm that there is no solder adhesion before turning on the power supply. Proofing of automotive PCBs

If it is necessary to add peripheral components to replace the damaged part inside the integrated circuit, small components should be selected, and the wiring should be reasonable to avoid unnecessary parasitic coupling, especially to deal with the grounding terminal between the audio amplifier integrated circuit and the pre-amplification circuit.

Do not easily judge that the integrated circuit has been damaged, because the vast majority of integrated circuits are directly coupled, once a circuit is abnormal, it may lead to multiple voltage changes, and these changes are not necessarily caused by the damage of the integrated circuit, and in some cases, when the voltage of each pin is measured to be consistent with or close to the normal value, it does not necessarily mean that the integrated circuit is good. Because some soft faults do not cause a change in DC voltage.

When measuring the voltage or testing the waveform with an oscilloscope probe, the pen or probe should not cause a short circuit between the pins of the integrated circuit due to sliding, and it is best to measure on the peripheral printed circuit directly connected with the pins.

Take Your Projects to New Heights with XPCB Limited

XPCB Limited offers top-notch PCB manufacturing, quick-turnaround prototyping, and turnkey PCBA services designed to make your projects shine. Count on us to bring your ideas to life with efficiency and quality. Your success matters to us, and we’re here to make your innovation journey smooth and rewarding.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2023 - XPCB Limited All Right Reserve