- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

Advances in packaging technology resulting in finer board geometry, including the various forms of high-density interconnection (HDI), have combined with increasing data rates to put significant pressure on the electrical test area. Fixture construction is more expensive and requires improved process control. Advanced test methods, such as radio frequency (RF) impedance testing, are more often required. Global price competition demands reduced costs. Meanwhile, original equipment manufacturers (OEMs) demand that board manufacturers accept increased liability for defective products—thereby demanding improved fault coverage.

This chapter is devoted to the why, what, where, when, and how of current electrical test methods useful in meeting these requirements.

Bare board test engineers are currently confronting significant changes in test requirements that derive from changes in the product itself. Notable among these changes are those driven by the growth of various HDI technologies. Examples of common HDI applications are direct chip attach (DCA), high-density ball grid array (BGA), and variants of these often referred to as chip scale packaging (CSP). In addition, higher-density input/output (I/O) connectors are commonly applied.

Image 3: Flex bare board testing

In addition to the changes in physical geometry, HDI also implies increasingly high data rates and clock speeds.Advanced means are being applied that verify not only the ability of the product to interconnect electronic components, but to do so in a manner that guarantees signal fidelity. An analogy is possible comparing the impact of HDI on board technology with the impact of the sound barrier on aerodynamic flight. This analogy is readily applied to final electrical testing. It was popularly imagined that the sound barrier was impassible, or could be passed only by Buck Rogers in his silver rocket—that beyond the speed of sound was no place for an airplane to go.

As it turned out, passing the sound barrier was difficult, and required rethink ing many aerodynamic principles. But the resulting vehicles are still recognizable as aircraft. They have wings, they burn fuel. They meet all of the objectives of earlier craft, and do so in a superior manner. The test processes that are resulting from the impacts of HDI upon final electrical testing are similarly recognizable evolutions of previous methods, employing familiar base technologies, but in new combinations and with added features that actually improve test coverage rather than diminishing it.

Image 2: BGA assembly on bare board

Proposals have circulated for radical new measurement approaches to electrical testing. These have included the use of electron beams, laser-stimulated photoelectric effects, and gas plasma techniques in configurations similar to existing flying probers. In each case, the board is scanned without use of a custom test fixture.To date, all of these methods involve compromise of fault coverage, or add little or no fine-pitch performance beyond conventional methods. Relaxation of test criteria is not a relief available to most users. HDI product types demand increased fine-pitch capability.

These finer trace and via geometries increase the risk of latent defects and increase interest in measurement methods most sensitive to precursor symptoms of such defects. As a result, none of these approaches has seen widespread adoption. Rather than witnessing radical breakthroughs, the market has seen a steady improvement in the availability of software and hardware tools that provide for the effective ombination of the best features of conventional test systems and increased availability of test systems dedicated to specialty markets, in particular the small-format laminated chip carrier product type.

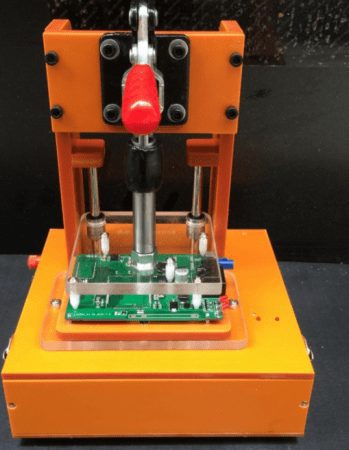

Image 3: PCB test fixture

Take Your Projects to New Heights with XPCB Limited

XPCB Limited offers top-notch PCB manufacturing, quick-turnaround prototyping, and turnkey PCBA services designed to make your projects shine. Count on us to bring your ideas to life with efficiency and quality. Your success matters to us, and we’re here to make your innovation journey smooth and rewarding.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve