- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

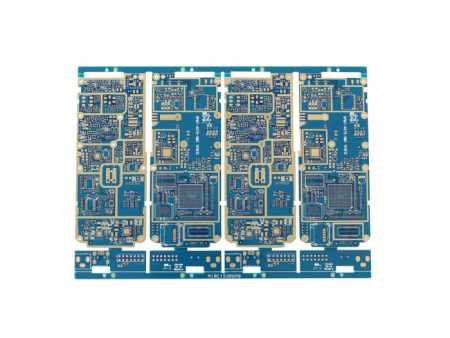

In the world of advanced electronics, the push for miniaturization and enhanced functionality has led to significant innovations in printed circuit board (PCB) design and manufacturing. Among these advancements, blind vias and buried vias stand out as essential technologies that enable the development of high-density interconnect (HDI) PCBs. These specialized via structures play a critical role in achieving compact, multi-layered designs with improved electrical performance. This blog delves into the importance of blind and buried vias in complex PCB manufacturing and how they contribute to high-density interconnections.

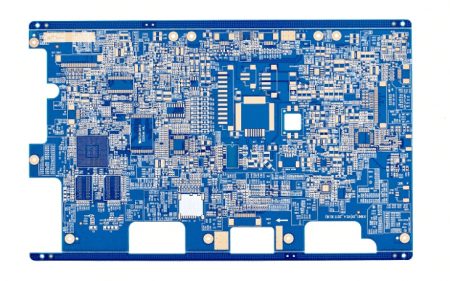

Vias are small holes drilled into a PCB to create electrical connections between layers. In traditional PCBs, through-hole vias pass entirely through the board. While effective, these vias occupy valuable space on all layers, limiting design flexibility and density. Blind and buried vias, however, offer advanced alternatives:

By minimizing surface disruption and optimizing layer interconnects, blind and buried vias enable designers to achieve more compact and efficient PCB layouts.

The fabrication of blind and buried vias requires advanced manufacturing techniques and precise control. Key challenges include:

To overcome these challenges, manufacturers employ state-of-the-art equipment and processes such as:

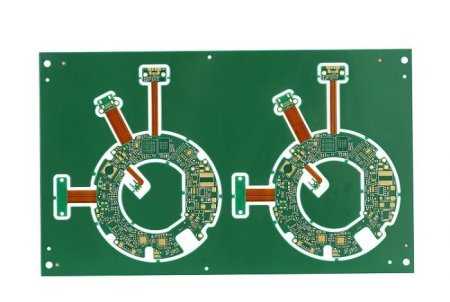

Blind and buried vias are indispensable in a variety of industries and applications:

Implementing blind and buried vias requires expertise in HDI PCB manufacturing. When selecting a manufacturing partner, consider the following:

Blind and buried vias are essential technologies for achieving high-density interconnections in complex PCB manufacturing. By optimizing space utilization and enhancing electrical performance, these vias enable the creation of compact, high-performance electronic devices that meet the demands of today’s market.

Whether you are designing consumer electronics, automotive systems, or medical devices, leveraging blind and buried via technology can elevate your products to new heights. Partnering with a skilled and experienced PCB manufacturer ensures that your designs are brought to life with precision and reliability, paving the way for innovation and success.

XPCB Limited: Your Partner for Turnkey PCBA Services and Advanced PCB Solutions

Looking for a reliable partner to bring your PCB projects to life? XPCB Limited offers end-to-end turnkey PCBA services and advanced PCB manufacturing solutions. From prototype development to full-scale production, we ensure unparalleled quality and efficiency. Choose XPCB Limited to simplify your workflow and achieve outstanding results for every project.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve