- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

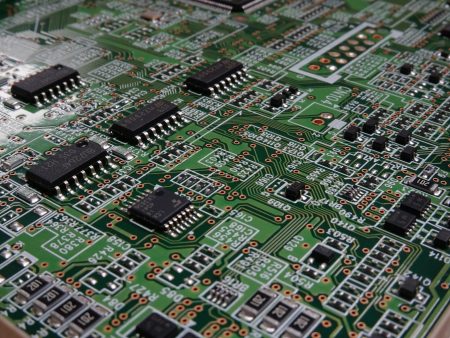

In today’s fast-paced electronics industry, small and medium-sized enterprises (SMEs) face unique challenges when it comes to manufacturing. As technology continues to advance, the demand for high-quality electronics is on the rise. For many SMEs, partnering with a one-stop surface mount device (SMD) service provider can be a game-changer, streamlining production processes and enhancing product quality. This blog will explore the factors SMEs should consider when choosing a one-stop SMD service, helping them make informed decisions that can positively impact their business.

One-stop SMD services offer a comprehensive solution for electronics manufacturing, encompassing design, prototyping, assembly, testing, and logistics. These services are particularly beneficial for SMEs that may not have the resources to manage each aspect of the production process independently. By consolidating services under one roof, SMEs can reduce lead times, minimize costs, and enhance collaboration.

Before selecting a one-stop SMD service provider, SMEs should assess their specific needs. This includes understanding the types of products they manufacture, production volumes, and any unique requirements. Questions to consider include:

What types of products are you producing?** Understanding the complexity and scale of your products can help you find a provider with relevant experience.

What is your production volume?** Determine whether you need small-batch production or large-scale manufacturing.

What are your timelines?** Assess how quickly you need prototypes and final products to be delivered.

By defining these needs, SMEs can better evaluate potential service providers.

When choosing a one-stop SMD service, it’s essential to evaluate the expertise and experience of the provider. An experienced partner can navigate the complexities of electronics manufacturing more effectively, ensuring high-quality outcomes. Consider the following:

Industry Experience: Look for a provider with a proven track record in your industry. Familiarity with specific market demands and standards can make a significant difference.

Technical Skills: Assess the technical capabilities of the provider. This includes their knowledge of the latest technologies, materials, and processes used in SMD manufacturing.

Quality is paramount in electronics manufacturing, especially in a market where reliability is critical. When selecting a one-stop SMD service, SMEs should investigate the provider’s quality assurance measures:

Certifications: Verify if the provider holds relevant certifications, such as ISO 9001, IPC-A-610, or other industry standards. These certifications indicate a commitment to quality and continuous improvement.

Testing Procedures: Inquire about the testing processes in place. A comprehensive quality control process ensures that each product meets established standards before delivery.

While cost is an important factor, it should not be the sole criterion for selection. SMEs need to assess the overall value offered by a one-stop SMD service. Consider the following:

Transparent Pricing: Look for providers that offer clear and transparent pricing structures. Avoid those with hidden fees that can inflate costs unexpectedly.

Cost vs. Quality: While it may be tempting to choose the lowest bidder, prioritize quality and reliability. A higher-quality product can lead to fewer returns and greater customer satisfaction, ultimately saving money in the long run.

Effective communication is crucial in any partnership. When choosing a one-stop SMD service, SMEs should assess the provider’s communication practices:

Accessibility: Ensure that the provider is easily accessible for questions and support throughout the production process.

Project Management: A good service provider should have a dedicated project manager who acts as a point of contact, facilitating communication and ensuring smooth operations.

As SMEs grow, their manufacturing needs may evolve. Choosing a one-stop SMD service that offers scalability and flexibility can be beneficial:

Adapting to Change: Assess whether the provider can accommodate changes in production volume or product design. Flexibility in adapting to changing market conditions can be a significant advantage.

Future Growth: Consider the provider’s ability to scale up production as your business expands. A partner that can grow with you will help ensure continuity and reduce the need for frequent supplier changes.

Finally, don’t underestimate the power of customer feedback. Researching customer reviews and testimonials can provide valuable insights into the reliability and performance of a potential one-stop SMD service provider:

Case Studies: Ask for case studies or examples of similar projects they have completed. This can help you gauge their capability and experience in your specific industry.

Client References: Request references from previous clients. Speaking directly with past customers can provide a clearer picture of what to expect.

Choosing a one-stop SMD service provider is a significant decision for small and medium-sized enterprises. By carefully assessing specific needs, evaluating expertise, and considering factors such as quality assurance, cost, communication, and scalability, SMEs can make informed choices that enhance their manufacturing processes.

In a competitive landscape, partnering with the right SMD service provider can not only improve efficiency but also lead to better product quality and customer satisfaction. As SMEs navigate this crucial decision, thorough research and careful consideration will be their best allies in achieving long-term success.

Make Your PCB Dreams a Reality with XPCB Limited

XPCB Limited is your go-to partner for turning your PCB dreams into reality. Our streamlined PCB manufacturing process, combined with quick-turnaround prototyping and turnkey PCBA services, ensures that your projects come to life with ease. Trust in our expertise and dedication to quality as we help you achieve your PCB goals. Join us and experience the difference with XPCB Limited.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve