In the realm of modern electronics, printed circuit boards (PCBs) form the backbone of virtually every device. As industries demand smarter, more compact, and robust solutions, PCB technologies have evolved to meet these needs. Two standout innovations—Flex PCBs and Rigid-Flex PCBs—offer unmatched versatility, catering to a wide range of applications.

This blog provides an in-depth look at these PCB types, their features, advantages, and how they are transforming industries worldwide.

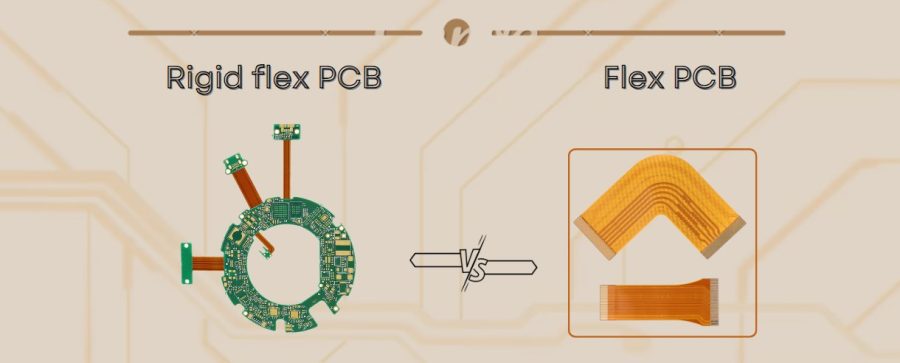

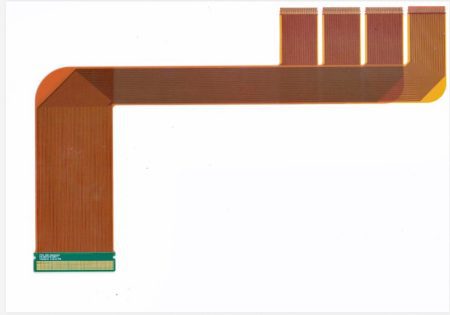

What Are Flex PCBs?

Flex PCBs, or flexible printed circuit boards, are thin, lightweight, and bendable circuits designed to fit into compact and unconventional spaces. They use flexible substrates like polyimide, which allows them to withstand bending, folding, and dynamic movement without breaking.

Key Features of Flex PCBs:

- Flexibility: Adaptable to curved or irregular surfaces.

- Lightweight: Ideal for portable and wearable devices.

- Durability: Withstands vibration and mechanical stress.

- Space Efficiency: Reduces the need for connectors and wiring.

Flex PCBs are especially valuable in industries that prioritize compact, reliable, and high-performance electronics.

What Are Rigid-Flex PCBs?

Rigid-Flex PCBs combine the best features of rigid and flexible PCBs into a single unit. They consist of multiple layers of flexible circuits connected to rigid sections, offering structural support and the ability to bend or fold.

Key Features of Rigid-Flex PCBs:

- Hybrid Design: Combines rigidity and flexibility for optimal performance.

- Durability: Handles extreme environmental conditions and stress.

- Compact and Lightweight: Eliminates bulky connectors and cables.

- Enhanced Signal Integrity: Reduces interference and signal loss.

Rigid-Flex PCBs are designed for complex applications where reliability and space constraints are critical.

Flex and Rigid-Flex PCBs: A Comparative View

| Feature | Flex PCB | Rigid-Flex PCB |

|---|---|---|

| Flexibility | Fully flexible | Partially flexible |

| Durability | Moderate to high | Extremely high |

| Cost | Lower initial cost | Higher upfront cost |

| Applications | Simple and dynamic designs | Complex, multi-layer, high-reliability systems |

| Assembly Complexity | Moderate | Simplified for multi-functional systems |

Both PCBs offer distinct advantages depending on the application, with Rigid-Flex PCBs excelling in more demanding environments.

Applications of Flex and Rigid-Flex PCBs

1. Consumer Electronics

- Flex PCBs: Power compact devices like smartphones, tablets, foldable screens, and wearable tech.

- Rigid-Flex PCBs: Enable innovative designs in foldable phones, advanced gaming systems, and smart home devices.

2. Automotive Industry

- Flex PCBs: Used in LED lighting systems and flexible wiring harnesses.

- Rigid-Flex PCBs: Integral to ADAS, infotainment systems, EV battery management, and autonomous vehicle technologies.

3. Medical Devices

- Flex PCBs: Support portable diagnostic tools and fitness trackers.

- Rigid-Flex PCBs: Essential in implantable devices, surgical instruments, and advanced imaging systems.

4. Aerospace and Defense

- Flex PCBs: Found in compact navigation tools and communication systems.

- Rigid-Flex PCBs: Used in mission-critical systems like radar, satellites, and avionics.

5. Industrial Automation

- Flex PCBs: Power compact sensors and controllers.

- Rigid-Flex PCBs: Facilitate robust robotics, control systems, and IoT-enabled industrial setups.

Advantages of Comprehensive PCB Solutions

Flex PCBs:

- Cost-Effective for Simple Applications: Ideal for dynamic but less complex systems.

- Lightweight and Compact: Reduces the overall device footprint.

Rigid-Flex PCBs:

- Enhanced Reliability: Reduces points of failure, making them suitable for critical systems.

- Design Freedom: Combines rigid and flexible features to tackle complex layouts.

- Reduced Assembly Costs: Streamlines manufacturing by integrating multiple functions into one PCB.

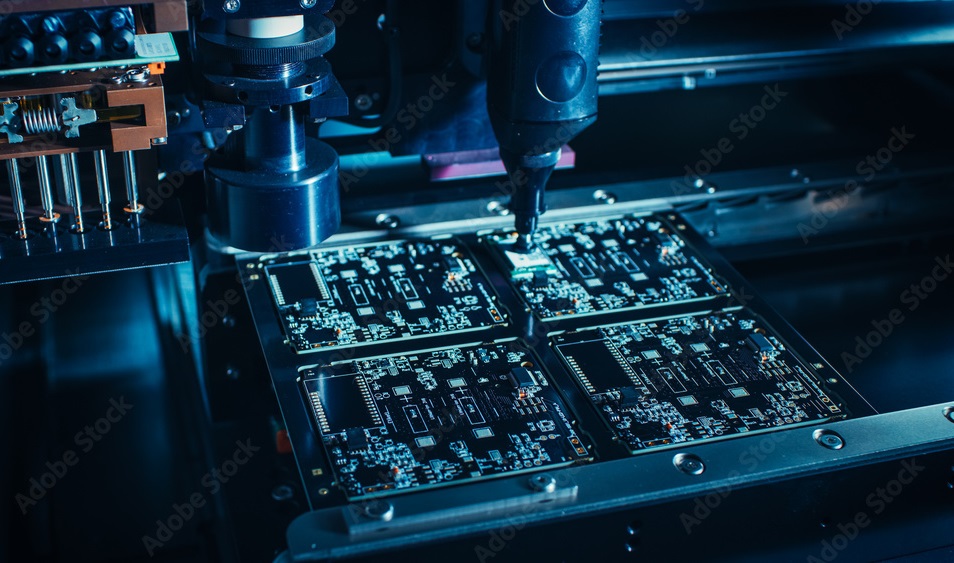

Challenges in Implementation

- Manufacturing Complexity:

Both Flex and Rigid-Flex PCBs require precise manufacturing techniques. Rigid-Flex PCBs, in particular, demand expertise in balancing rigid and flexible layers. - Cost Considerations:

While Flex PCBs are generally cost-effective, Rigid-Flex PCBs involve higher upfront costs due to their complexity. - Material Selection:

Selecting the right materials that balance flexibility, durability, and thermal stability is crucial. - Design Challenges:

Engineers must account for bending, stress points, and electrical performance when designing these PCBs.

Future Trends in PCB Technologies

- Advanced Manufacturing:

Innovations in 3D printing and additive manufacturing are enabling more intricate and customized PCB designs. - Eco-Friendly Solutions:

With growing concerns about electronic waste, research is focusing on recyclable materials and sustainable PCB production methods. - Integration with IoT and AI:

The proliferation of IoT and AI-driven devices is driving demand for PCBs with greater connectivity and computational capabilities. - High-Density Interconnects (HDI):

Both Flex and Rigid-Flex PCBs are increasingly incorporating HDI technology to meet the demands of miniaturization and high-speed data transmission.

Conclusion

From Flex PCBs enabling lightweight, compact designs to Rigid-Flex PCBs powering the most complex and demanding systems, PCB technologies are the foundation of modern innovation. Their adaptability and reliability make them indispensable across industries ranging from consumer electronics and automotive to aerospace and healthcare.

As technology continues to evolve, comprehensive PCB solutions will remain at the forefront, driving progress and enabling new possibilities. Whether you’re building a flexible wearable or a robust automotive control system, Flex and Rigid-Flex PCBs are your go-to solutions for the future of electronics.