- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

In today’s rapidly advancing technological world, Printed Circuit Boards (PCBs) are the unsung heroes powering countless devices we use daily. Among the various types of PCBs, High-Density Interconnect (HDI) PCBs and Multilayer PCBs are at the forefront of innovation, enabling compact, high-performance, and reliable solutions for industries ranging from consumer electronics to aerospace. At XPCB, we pride ourselves on being a trusted leader in manufacturing HDI and multilayer PCBs, setting benchmarks in quality, precision, and innovation.

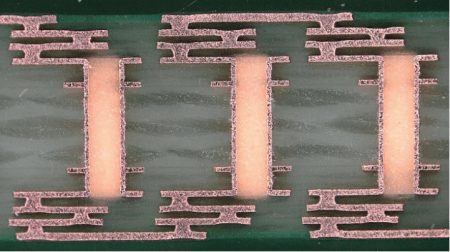

HDI PCBs are characterized by their high wiring density, achieved through advanced microvia and laser drilling technologies. These boards are designed to accommodate more components in a smaller area, making them essential for compact and complex electronic devices.

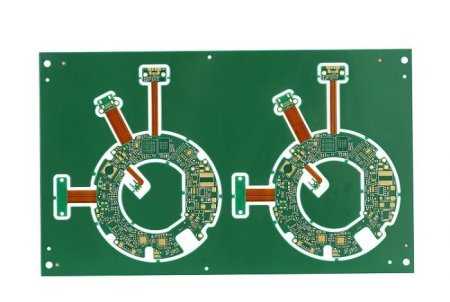

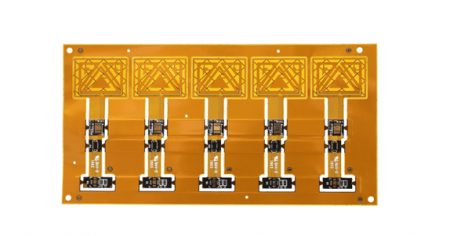

Multilayer PCBs consist of multiple conductive layers, separated by insulating materials and laminated into a single board. With their ability to handle complex circuits and high electrical demands, multilayer PCBs are indispensable in industries such as automotive, medical, and telecommunications.

At XPCB, we bring decades of expertise to the design and manufacturing of HDI and multilayer PCBs. Our commitment to innovation, quality, and customer satisfaction sets us apart in the competitive landscape.

4 layer Flex Circuit with HDI

As technology evolves, the demand for smaller, faster, and more efficient PCBs will continue to grow. Innovations such as flexible PCBs, hybrid designs, and advancements in material science are shaping the future of the industry. At XPCB, we stay ahead of these trends, investing in research and development to provide cutting-edge solutions.

HDI and multilayer PCBs are integral to the technological advancements shaping our world. At XPCB, we take pride in leading the industry with our expertise, commitment to quality, and innovative manufacturing processes. Whether you’re developing next-generation consumer electronics or pioneering solutions in aerospace, XPCB is your reliable partner for all your PCB needs.

Contact us today to learn how we can help turn your vision into reality with our advanced HDI and multilayer PCB manufacturing capabilities.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve