- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

Menu

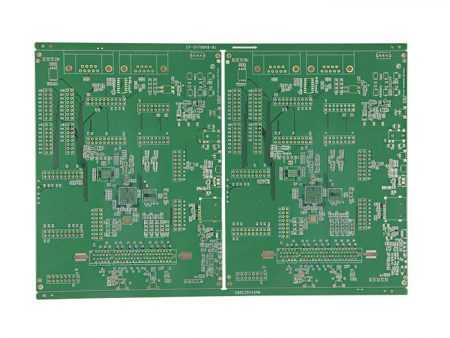

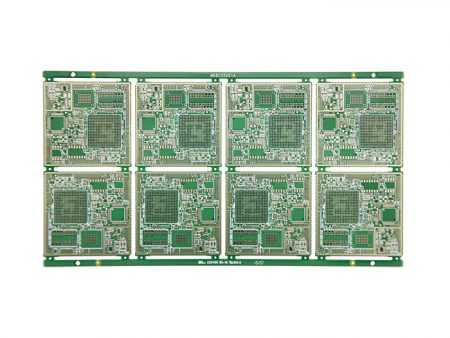

HDI (High-Density Interconnector) PCBs refer to printed circuit boards (PCBs) that have an increased number of interconnections per unit area compared to traditional PCBs. These PCBs are characterized by their high layer count and fine line widths and spaces, allowing for improved electrical performance and miniaturization.

Reduced Size: HDI rigid boards allow for the miniaturization of electronic devices, making them more compact and portable.

Enhanced Electrical Performance: The increased number of interconnections in HDI rigid boards allows for the routing of signals in a more efficient manner, reducing signal loss and improving signal integrity.

Cost Savings: HDI rigid boards can be more cost-effective than traditional PCBs due to their reduced size and weight.

Increased Manufacturing Flexibility: HDI rigid boards can be produced using a variety of manufacturing techniques, such as multi-layer lamination and through-hole plating, providing manufacturers with more flexibility in PCB design and production.

HDI (High-Density Interconnector) printed circuit boards have gained significant attention in the electronics industry due to their exceptional performance and compact design. As the demand for high performance and miniaturization continues to grow.

One of the primary reasons why HDI rigid PCBs have gained popularity is the increased density they offer. By stacking multiple layers through microvia technology and blind vias, manufacturers can achieve higher component density, reducing the overall size of the printed circuit board. This miniaturization allows designers to create more compact and space-efficient electronic devices.

One of the key advantages of HDI rigid boards is their ability to integrate multiple layers, increasing the complexity of the printed circuit board design. With conventional PCB technologies, manufacturers are limited to a maximum number of layers, usually five or six. However, HDI rigid boards can incorporate up to 24 layers, allowing for the integration of more complex circuitry and reducing the size and weight of the devices.

Signal integrity is a critical concern for designers working on high-speed electronic devices. HDI rigid boards offer significant improvements in terms of signal integrity. The use of microvias and blind vias allows for shorter signal paths, resulting in reduced signal loss and higher data transfer speeds. Additionally, the controlled impedance provided by HDI rigid PCBs ensures consistent signal propagation, resulting in improved overall performance.

HDI rigid boards are known for their enhanced mechanical durability. The microvias and blind vias used in HDI rigid PCBs provide structural integrity, preventing delamination and cracking. Additionally, the reduced size of the components and increased layer count contribute to a more robust design. This durability ensures longer lifespan and reliable performance even in demanding applications.

Contrary to popular belief, HDI rigid PCBs can actually result in cost savings for manufacturers. The increased density and improved signal integrity allow for the use of smaller components, thereby reducing the overall material cost and assembly complexity. Additionally, the shorter signal paths and reduced board sizes result in reduced power consumption, further contributing to the cost-effectiveness of HDI rigid boards.

In conclusion, HDI rigid boards have emerged as a superior development trend in the printed circuit board industry. The ability to provide higher density, multilayer integration, improved signal integrity, enhanced mechanical durability, and cost reduction make them an ideal choice for high-performance and compact electronic devices. As technology continues to advance, we can expect further advancements in HDI rigid PCB technology to cater to the growing requirements of electronic systems.

Simplify Your PCB Journey with XPCB Limited

XPCB Limited simplifies the PCB process for you. With our quick-turnaround prototyping and turnkey PCBA services, we ensure that your projects move forward smoothly and efficiently. Trust our commitment to quality and timeliness as we help you bring your designs to life. Choose XPCB Limited for a hassle-free PCB experience.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2023 - XPCB Limited All Right Reserve