- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

How High-Quality Flex PCBs Are Made? Not only are customers concerned about this problem, but PCB manufacturers are also trying to think about this problem.

In the process of circuit board proofing production, many problems are often encountered. Such as short circuits, open circuits, pads falling off, poor tinning, etc., so engineers prefer to choose those manufacturers with high production quality and fast speed when selecting circuit board proofing factories. This can save a lot of unnecessary trouble, so how do you judge that the board produced by the circuit board proofing factory is a high-quality flex PCB product?

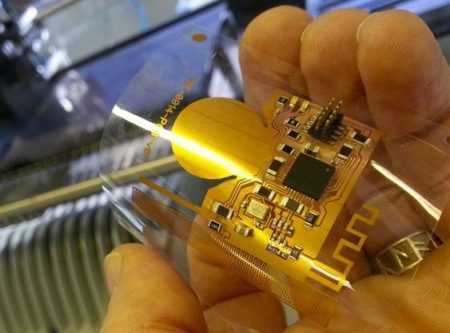

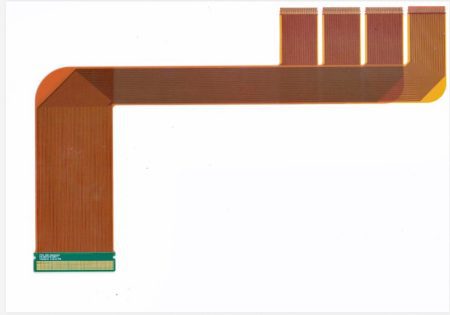

Flex printed circuit boards (PCBs) are a unique type of printed circuit board that are designed to be flexible and bendable. These PCBs have gained popularity in various industries due to their ability to handle complex geometries and tight spaces, making them suitable for a wide range of applications. In this blog post, we will explore the process of how high-quality flex PCBs are made.

The first step in making a high-quality flex PCB is designing it. The designer must consider various factors, such as the required flexibility, thickness of the board, and overall functionality. It is crucial to design the PCB with careful consideration of electrical and mechanical constraints to ensure its optimal performance.

Choosing the right materials is crucial for creating a high-quality flex PCB. The materials typically include a flexible substrate, such as polyimide or polyester, and a layer of copper conductor patterns. The substrate is selected based on its flexibility and resistance to harsh chemicals and temperature variations. The copper conductor patterns are formed using techniques such as photolithography or etching.

Flex PCBs can have multiple layers, depending on the application. The layer configuration is typically designed to minimize the board’s overall thickness while maintaining the required functionality. The layers are connected using flexible joints, such as vias or traces, to ensure the PCB remains stable even when bent or twisted.

Flex PCBs are commonly exposed to high temperatures, which can affect their performance and stability. Therefore, it is crucial to include effective thermal management techniques in the design. Techniques such as heat sinks, thermal vias, or thermal pads can be used to dissipate heat and prevent thermal degradation.

Once the design is complete and the materials have been selected, the flex PCB can be assembled and tested. The assembly process involves connecting electronic components, such as resistors, capacitors, and integrated circuits, to the board. Testing is performed to ensure the board’s functionality, electrical stability, and compliance with required specifications.

Quality control is an important aspect of the manufacturing process to ensure the production of high-quality flex PCBs. Various tests, such as visual inspection, electrical testing, and thermal cycling, are performed to detect any defects or issues. By maintaining strict quality control measures, manufacturers can ensure the reliability and durability of the PCBs.

Finally, the flex PCBs are packaged and shipped to the client or manufacturer’s end. Packaging plays a vital role in protecting the PCB from damage during transportation and storage. The packaging should be designed to protect the board from mechanical stresses, moisture, and environmental conditions that could compromise its quality.

In conclusion, high-quality flex PCBs are made through a meticulous process of design, materials selection, layer configuration, thermal management, assembly, testing, quality control, and packaging. By following these steps and adhering to strict quality standards, manufacturers can produce flex PCBs that meet the specific requirements and demands of various applications.

Discover a World of Possibilities with XPCB Limited

At XPCB Limited, we’re here to help you explore new horizons. Our advanced PCB manufacturing, rapid prototyping, and turnkey PCBA solutions make it easy for you to turn your ideas into reality. Trust us to deliver excellence and reliability every step of the way. Join us and experience the power of innovation with XPCB Limited by your side.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve