- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

Menu

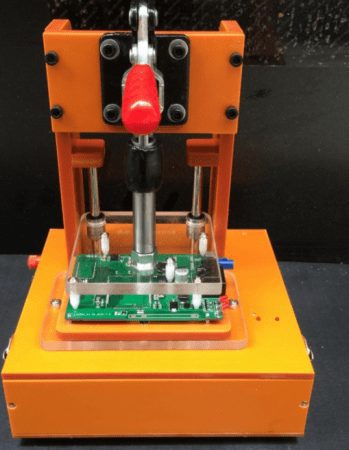

PCBA functional test refers to the test target PCBA board to provide simulation of the operating environment (excitation and load), so that it works in a variety of design states, so as to obtain the parameters of each state to verify the function of the PCBA target board test method. In short, it is to load the appropriate excitation on the PCBA target board and measure whether the output response meets the requirements.

There are two methods of PCBA function testing, wired testing and wireless testing.

Wired test fixtures have always been the industry standard for functional test fixtures.

On PCBAs with low probe counts or prototypes where design changes are possible, wired test fixtures provide an economical approach because they avoid non-engineering (NRE) costs. The challenge with wired lamps is that as the signal frequency increases, crosstalk and coupling issues may increase. This is because the wires are wired below the probe plate, and the coupling and crosstalk increase as the frequency increases.

Engineers developed wireless test fixtures to address the limitations of wired test fixtures.

In wireless fixations, a multilayer PCB called a transfer board (T board) replaces the signal line group on the underside of the wired probe board. Automatic PCB design software is used to route circuit routes when wiring is replaced. The double-ended probe connects the PCBA under test to the T-Board.

Wireless devices are generally more reliable than wired fixtures because PCB designers can precisely control how each track is wired at the bottom of the T-board, thereby isolating troublesome signals. Duplicate fixtures are performed almost equally, and the electrical parameters are very consistent because there are no wires and their resulting variations. Reduced ground and crosstalk noise results in faster signal rebound, which is especially important in low voltage test applications.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2023 - XPCB Limited All Right Reserve