- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

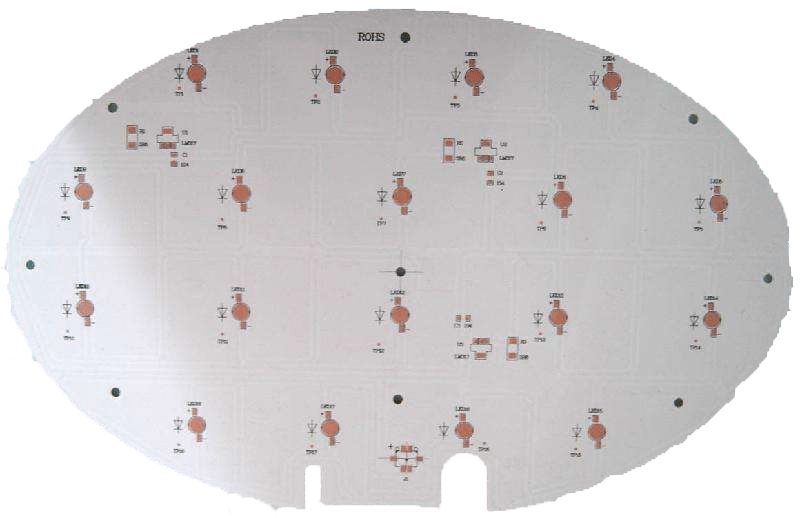

Aluminum PCB is one of type in metal core printed circuit board, featuring prominent heat dissipation ability and durability. It is considered as optimal choice for the applications involving heat dissipation because they provide an ideal exit of the heat with the help of dielectric, maintaining the overall temperature of the project design. Below are details about Aluminum PCB’s features, structure and applications.

PCB aluminum-based copper clad laminate is a metal circuit board material composed of copper foil, thermally conductive insulating layer and metal substrate. Its structure is divided into three layers:

① Circuit Layer : equivalent to the copper clad laminate of an ordinary PCB, the thickness of the circuit copper foil is loz to 10oz.

② Dielectric Layer : The insulation layer is a layer of low thermal resistance thermally conductive insulating material. Thickness: 0.003″ to 0.006″ inches is the core design of aluminum-based copper clad laminates, which has been certified by UL.

③ Base Layer: It is a metal substrate, generally aluminum or copper as an option. Aluminum-based copper clad laminate and traditional epoxy glass cloth laminate, etc.

The PCB aluminum substrate is composed of a circuit layer, a thermally conductive insulating layer and a metal base layer. The circuit layer (ie copper foil) is usually etched to form a printed circuit to connect the various components of the assembly. Generally, the circuit layer requires a large current-carrying capacity, so thicker copper foil should be used, with a thickness of 35μm~ 280μm; the thermal insulation layer is the core technology of the PCB aluminum substrate. It is generally composed of a special polymer filled with special ceramics. It has low thermal resistance, excellent viscoelasticity, thermal aging resistance, and can withstand mechanical and thermal stress.

T-101, T-111, T-112, T-113, T-114 and T-200, T-300, T-400, T-500, T-600 and other high-performance PCB aluminum substrates are thermally conductive and insulating layers This technology is used to make it have extremely excellent thermal conductivity and high-strength electrical insulation performance; the metal base layer is the supporting member of the aluminum substrate, which requires high thermal conductivity, usually aluminum plate, but also copper plate (where copper plate can Provide better thermal conductivity), suitable for conventional machining such as drilling, punching and cutting. Compared with other materials, PCB materials have incomparable advantages. Suitable for surface mount SMT public art of power components. No radiator is needed, the volume is greatly reduced, the heat dissipation effect is excellent, and the insulation performance and mechanical performance are good.

XPCB Limited is specialist in multilayer Aluminum PCB, welcome contact us [email protected] for quote anytime.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve