- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

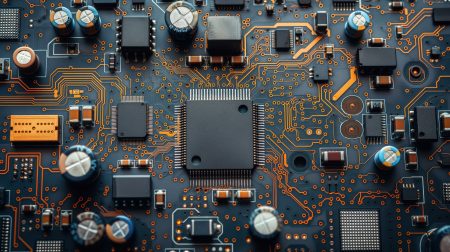

Flexible Printed Circuit Boards (FPCBs) have become increasingly popular in various industries, particularly in consumer electronics, medical devices, and automotive applications. Their lightweight and space-saving designs provide significant advantages over traditional rigid PCBs. However, the assembly of FPCBs presents unique challenges that manufacturers must navigate to ensure high-quality products. This blog explores these challenges in detail, along with strategies to overcome them.

One of the primary challenges in FPCB assembly lies in the materials used. FPCBs are typically made from flexible materials like polyimide, which can be sensitive to temperature changes.

Thermal Sensitivity: FPCBs require precise thermal management during soldering processes. Excessive heat can deform the substrate, leading to failures in the circuit. Manufacturers need to control the temperature during soldering and reflow processes meticulously to avoid damaging these sensitive materials.

Mechanical Flexibility: While flexibility is an advantage, it also poses difficulties. The bending and twisting during assembly can lead to micro-cracks or other physical damage to the board or components. Special handling and fixtures may be necessary to stabilize FPCBs during assembly.

The assembly process for FPCBs is generally more intricate than that for rigid PCBs, primarily due to their unique shapes and configurations.

Component Placement: FPCBs often incorporate a variety of components, including tiny surface-mounted devices (SMDs) and through-hole components. Ensuring accurate placement of these components can be challenging, especially on irregularly shaped boards.

Welding Techniques: The soldering techniques used in FPCB assembly may differ from those used for traditional PCBs. For example, the need for low-temperature soldering and alternative joining methods, such as conductive adhesives, can complicate the process.

FPCB assembly often requires specialized equipment, which can be a barrier for some manufacturers.

Specialized Machines: Standard pick-and-place machines may not be suitable for FPCBs due to their flexibility and varying thicknesses. Manufacturers may need to invest in specialized equipment, which can lead to higher capital costs.

Calibration and Maintenance: The specialized equipment used for FPCB assembly requires regular calibration and maintenance to ensure accuracy. This adds to the operational costs and complexity of the assembly process.

Ensuring the quality of assembled FPCBs is critical but presents its own set of challenges.

Inspection Difficulty: The flexible nature of FPCBs makes visual inspection more challenging. Defects such as misalignment, insufficient solder, or hidden component issues can be hard to detect. Manufacturers may need to invest in advanced inspection technologies, such as Automated Optical Inspection (AOI) and X-ray systems, to enhance quality control.

Testing for Reliability: FPCBs are often subjected to bending and flexing in their end-use environments. Therefore, reliability testing, including thermal cycling and mechanical stress tests, is crucial but can be more complicated than testing rigid PCBs.

The design of FPCBs is often more complex than that of traditional PCBs, which can lead to challenges during the assembly process.

Multi-layer Structures: Many FPCBs feature multi-layer designs to accommodate intricate circuitry. The assembly of multi-layer boards requires careful alignment and precision, which can complicate the manufacturing process.

Design Software: The software used for designing FPCBs must be capable of handling complex geometries and materials. This requirement can necessitate additional training and expertise for design engineers.

The unique challenges of FPCB assembly often lead to higher production costs, which can be a significant concern for manufacturers.

Higher Material Costs: Flexible materials tend to be more expensive than traditional PCB substrates. This increases the overall cost of the assembly process.

Increased Labor Costs: The need for specialized handling and additional quality control measures can drive up labor costs. Skilled workers are often required to manage the complexities of FPCB assembly effectively.

While these challenges are significant, there are several strategies that manufacturers can adopt to mitigate them:

Invest in Specialized Training: Providing training for assembly staff on handling flexible materials and operating specialized equipment can enhance quality and efficiency.

Implement Advanced Inspection Technologies: Investing in automated inspection systems can help detect defects early in the assembly process, reducing the risk of costly rework.

Optimize Design for Assembly (DFA): Working closely with design teams to optimize FPCB layouts can simplify assembly processes and reduce errors.

Collaborate with Material Suppliers: Engaging with material suppliers to understand the best practices for handling and assembling flexible materials can lead to improved outcomes.

The assembly of FPCBs presents unique challenges that require careful consideration and planning. By understanding these challenges and implementing effective strategies, manufacturers can enhance the efficiency and reliability of their FPCB assembly processes. As the demand for flexible circuit technologies continues to grow, addressing these challenges will be critical for staying competitive in the ever-evolving electronics market.

Discover a World of Possibilities with XPCB Limited

At XPCB Limited, we’re here to help you explore new horizons. Our advanced PCB manufacturing, rapid prototyping, and turnkey PCBA solutions make it easy for you to turn your ideas into reality. Trust us to deliver excellence and reliability every step of the way. Join us and experience the power of innovation with XPCB Limited by your side.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve