- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

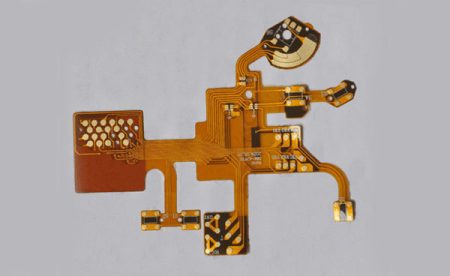

On the occasion of the miniaturization of electronic products, a considerable part of the surface mount of consumer products, due to the assembly space, the SMD is mounted on the flexible PCB to complete the assembly of the whole machine. The surface mount of the SMD on FPC has become one of the development trends of SMT technology. There are the following points for the process requirements and attention points of surface mount.

Features:

The requirements for placement accuracy are not high and the number of components is small. Component varieties are mainly resistors and capacitors, or there are individual special-shaped components.

Key Process:

Features:

There must be a MARK for substrate positioning on the FPC, and the FPC must be flat. It is difficult to fix the FPC and ensure consistency during mass production, and with high requirements fot the equipment requirements. In addition, it is difficult to control the printing solder paste and placement process.

Key Process:

1. FPC Fixation:

From the printing patch to the reflow soldering, the entire process is fixed on the pallet. The pallet used requires a small thermal expansion coefficient. There are two fixing methods. Use method A when the placement accuracy is above 0.65MM for QFP lead spacing. Use method B when the placement accuracy is less than 0.65MM for QFP lead spacing.

2. Solder Paste Printing:

The pallet is loaded with FPC, and there is a high temperature resistant tape for positioning on the FPC. So the height is inconsistent with the pallet plane. You must choose an elastic scraper when printing. The composition of the solder paste has a greater impact on the printing effect. Choose a suitable solder paste. In addition, printing template of the method B needs to be specially processed.

3. Mounting Equipment:

First, solder paste printing machine. Printing machine should have an optical positioning system, otherwise it will have a greater impact on the welding quality. Secondly, FPC is fixed on the pallet. There is always some tiny gaps, which is the biggest difference from the PCB substrate. The setting of equipment parameters will have a greater impact on the printing effect, placement accuracy, and welding effect. Therefore, the placement of FPC has strict requirements for process control.

In order to ensure assembly quality, it would be better to dry the FPC before mounting.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve