- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

As the world advances into the era of smart manufacturing, the role of printed circuit board assembly (PCBA) services has become pivotal in enabling sophisticated electronic systems. High-Density Interconnect (HDI) technology, combined with complex PCB manufacturing, forms the backbone of modern electronics, driving innovations in industries such as automotive, healthcare, consumer electronics, and industrial automation. This article explores the integration of HDI technology in PCBA services and how it aligns with the principles of smart manufacturing.

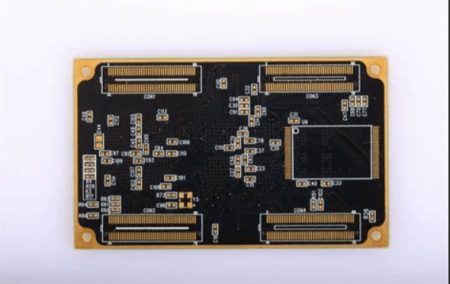

HDI technology is essential for achieving the miniaturization and high performance demanded by modern electronic devices. With features such as microvias, blind vias, buried vias, and fine line widths, HDI PCBs enable the creation of highly compact designs without compromising functionality. The adoption of HDI in PCBA services facilitates:

The integration of HDI technology into PCBA services presents several challenges:

1. Manufacturing Precision: HDI PCBs demand highly precise manufacturing techniques, including laser drilling for microvias and fine-line etching for dense trace routing. Achieving consistent quality in such complex processes requires advanced equipment and expertise.

2. Material Selection: Selecting materials that support HDI structures, such as low-loss laminates and high-performance copper foils, is critical. These materials must withstand multiple lamination cycles and provide the necessary electrical and thermal properties.

3. Cost Management: The advanced processes and materials associated with HDI manufacturing often result in higher production costs. Balancing cost efficiency with performance requirements is a constant challenge.

4. Inspection and Quality Assurance: Inspecting the intricate features of HDI PCBs, such as microvias and thin traces, requires sophisticated non-destructive testing methods like X-ray imaging and automated optical inspection (AOI).

Smart manufacturing leverages automation, IoT, artificial intelligence (AI), and data analytics to enhance efficiency, precision, and adaptability in production processes. When applied to PCBA services, smart manufacturing enables the seamless integration of HDI technology in the following ways:

1. Advanced Design Tools: AI-driven design software optimizes HDI layouts, predicting potential issues like signal integrity problems or thermal hotspots before manufacturing begins. Digital twins provide virtual prototypes, reducing the need for physical iterations.

2. Automated Assembly Lines: Automation in component placement, soldering, and testing ensures consistent quality and speeds up production. Robotic arms equipped with vision systems handle the delicate components of HDI PCBs with precision.

3. Real-Time Monitoring: IoT-enabled sensors on manufacturing equipment provide real-time data on temperature, humidity, and machine performance, ensuring optimal conditions for HDI PCB production.

4. Predictive Maintenance: AI algorithms analyze equipment data to predict potential failures, minimizing downtime and ensuring uninterrupted production of complex PCBs.

5. Enhanced Testing Capabilities: Smart manufacturing incorporates advanced testing systems like inline automated X-ray inspection (AXI) and 3D AOI, enabling thorough inspection of HDI features without slowing down the production line.

The convergence of HDI technology and smart manufacturing offers numerous benefits for PCBA services:

As industries continue to demand more advanced electronic systems, the integration of HDI technology in smart manufacturing is expected to evolve further. Key trends include:

The era of smart manufacturing represents a transformative phase for PCBA services, where the integration of HDI technology plays a critical role. By leveraging automation, AI, and advanced materials, manufacturers can overcome the challenges of complex PCB production while delivering innovative, high-performance solutions. As technology continues to evolve, the synergy between HDI and smart manufacturing will remain a driving force behind the next generation of electronic devices.

From Prototyping to Turnkey PCBA – XPCB Delivers Excellence

XPCB Limited is your go-to partner for PCB excellence. We provide a complete range of services, from quick-turn prototyping to turnkey PCBA, to meet the diverse needs of your projects. With an emphasis on innovation, quality, and customer satisfaction, XPCB ensures your PCBs are delivered on time and to specification. Start your journey to success with XPCB Limited.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

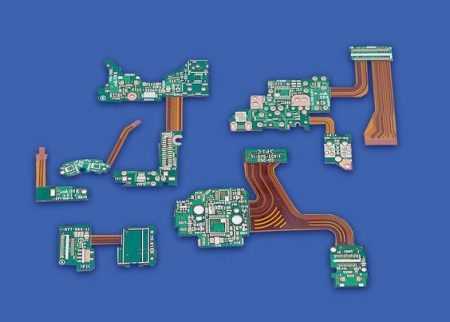

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve