- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

The process of PCB manual dip soldering is generally plug-in (or short-foot operation first) → dip soldering → cutting feet → repairing soldering → cleaning (measurement inspection)

(1) Plug-in: This part is because the PCB of each customer is different. It is not too specific. Simply put, the equipment that the plug-in will use. Some physical manufacturers generally use customized plug-in assembly lines. For those in small batches production customers, here I can give some tips to buy two aluminum profiles, and wash out a PCB slot (professional plug-in aluminum profile 200 yuan/m) after lathe processing. If conditions permit, you can first use the component forming machine to cut the feet of the component for forming operations. This can make the plug-in more beautiful and convenient, and it can save a lot of tin during the dipping soldering mentioned below!

(2) Welding: The welding part is the focus of my post. The equipment and solder needed are PCB manual dip soldering machine, tin bar, and flux.

Principle: Dip soldering is to use a tin furnace to melt a large amount of tin, immerse the soldering surface, and make the solder joints tin. Both plug-in technology and SMT red glue surface are required.

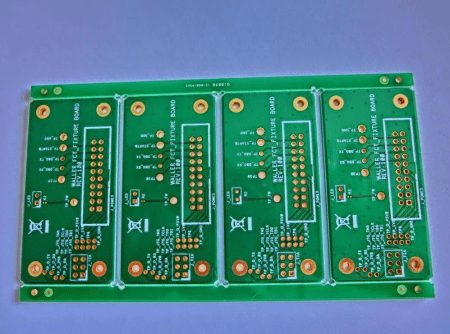

Introduction of dip soldering: Dip soldering is a method of dipping the PCB board with the components inserted in the melting tin furnace to complete many solder joints at one time.

Operation process: Manual dip soldering is a method in which a person holds a fixture to clamp the inserted PCB, and manually completes the dip soldering method.

The characteristics of manual dip soldering are simple equipment, simple operation, low investment, higher efficiency than manual soldering with a soldering iron, and beautiful solder joints!

(3) Foot cutting: The common cutting method in the market is to use a hand-push type circuit board cutting machine. Advantages of it is high efficiency, neat and beautiful cut feet. The cost may range from 3000-6000. Of course, diagonal pliers are also a good choice compared to small batch development and production.

(4) Repair soldering: After the PCB is cut to the feet, then the entire soldering process is completed. Next, we need to trim the PCB and observe the circuit board by visual inspection to see if there is any missing soldering, false soldering, or continuous soldering. It can be trimmed with a soldering iron. You can go through the tin furnace again if necessary.

(5) Cleaning and measurement: The repair welding part is just a simple trimming of the circuit board from the appearance. If you have high requirements for your own products, it still needs to be cleaned. The cleaning fluid is professional plate washing water, which can be treated with manual brush or ultrasonic cleaning equipment. (The cost of this part is relatively high, and it can be operated according to the actual situation)

Inspection and measurement: High-quality products need to be inspected by professional instruments. Commonly used testing instruments include oscilloscopes, withstand voltage testers, LCR digital bridges, and electronic load meters. Choose different instruments according to the tested functions. In this regard, you can communicate with professional instrument sellers. The above mentioned individuals have some personal experience in the sales of welding equipment for many years.

XPCB Limited is a manufacturer specializing in the production of high-precision double-sided, multi-layer and impedance, blind buried vias, and thick copper circuit boards. The products cover HDI, thick copper, backplanes, rigid-flex combined, buried capacitance and buried resistance, Golden Finger and other kinds of circuit boards, which can meet the needs of customers for all kinds of products.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve