- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

In the ever-evolving landscape of 3D printing technology, achieving high precision is a fundamental goal for both hobbyists and professionals. One of the unsung heroes in this realm is the rigid-flex printed circuit board (PCB). These innovative components play a crucial role in enhancing the performance, reliability, and overall precision of 3D printers. In this blog post, we’ll explore the importance of rigid-flex PCBs and how they contribute to printing excellence.

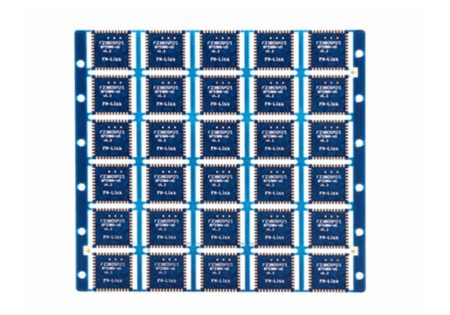

Rigid-flex PCBs combine the best of both rigid and flexible circuit technologies. They consist of layers of rigid and flexible substrates, allowing for a versatile design that can adapt to various shapes and sizes. This unique construction is particularly beneficial in 3D printers, where space is often limited, and the components must work harmoniously to achieve optimal performance.

One of the primary functions of rigid-flex PCBs in 3D printers is to provide structural stability. The rigid portions of the PCB support essential components like stepper motors and control units, ensuring they remain securely in place during operation. Meanwhile, the flexible sections can accommodate the printer’s dynamic movements, such as the shifting of the print head or the movement of the build platform. This combination minimizes vibrations and reduces the risk of misalignment, leading to higher printing precision.

Another significant advantage of rigid-flex PCBs is their ability to enhance signal integrity. In a 3D printer, numerous sensors and electronic components work in unison to monitor and control the printing process. Rigid-flex PCBs help maintain consistent signal paths, reducing noise and interference that can compromise the accuracy of data transmission. This ensures that the printer can respond quickly and accurately to commands, ultimately improving print quality.

3D printing involves high temperatures, particularly when melting materials like plastics or metals. Effective thermal management is vital to prevent overheating, which can lead to warping or deformation of printed parts. Rigid-flex PCBs can be designed with materials that dissipate heat efficiently, helping to regulate the temperature of critical components. By maintaining optimal thermal conditions, these PCBs contribute to the reliability and precision of the 3D printing process.

In the design of modern 3D printers, space and weight are crucial considerations. Rigid-flex PCBs allow for a more compact configuration, reducing the overall footprint of the printer without compromising functionality. This space-saving design is especially beneficial in smaller printers or those intended for portable use. Additionally, the lightweight nature of rigid-flex PCBs contributes to a lower overall weight, making it easier to integrate into various 3D printer models.

The versatility of rigid-flex PCBs extends beyond standard 3D printing applications. They can be tailored to accommodate different printing technologies, including fused deposition modeling (FDM), stereolithography (SLA), and selective laser sintering (SLS). This adaptability makes them an ideal choice for manufacturers looking to innovate and push the boundaries of what 3D printing can achieve.

As the 3D printing industry continues to grow, the demand for precision and reliability will only increase. Rigid-flex PCBs are at the forefront of this evolution, playing a crucial role in enhancing printing quality and performance. By providing structural stability, improving signal integrity, facilitating thermal management, and offering compact designs, rigid-flex PCBs are essential components that enable 3D printers to meet the high standards expected by users today.

In the quest for ever-greater precision in 3D printing, it is clear that rigid-flex PCBs will continue to be a key player, driving innovation and excellence in this exciting field. Whether you’re a seasoned professional or just starting your 3D printing journey, understanding the role of these components can provide valuable insights into the technology that powers your creations.

Your Trusted Partner for PCB Success: XPCB Limited

Let XPCB Limited be your guide to PCB success. Our comprehensive PCB manufacturing, rapid prototyping, and turnkey PCBA services are designed to meet your needs with ease. Count on us to deliver reliable solutions that exceed your expectations. With XPCB Limited, your journey to PCB excellence starts here.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve