- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

Menu

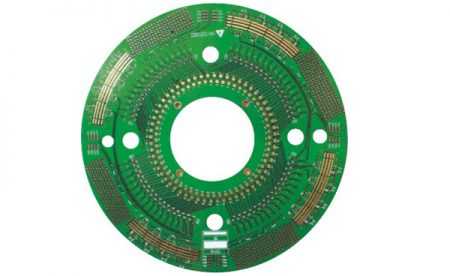

There are many common welding defects in circuit board processing. The following figure shows sixteen common welding defects.

The following is a detailed description of common welding defects, appearance characteristics, hazards, and possible causes.

1. Welding

a.) Appearance Characteristics: There is an obvious black boundary line between the solder and the lead of the component or the copper foil, and the solder is sunken toward the boundary.

b.) Hazards: Can not work properly.

c.) Possible Causes:

–The component leads are not cleaned, tinned or oxidized.

–The printed circuit board is not clean, and the sprayed flux is of poor quality.

2. Solder accumulation

a.) Appearance Characteristic: The solder joint structure is loose, white and dull.

b.) Hazards: Insufficient mechanical strength may cause false welding.

c.) Possible Causes:

–The solder quality is not good.

–The welding temperature is not enough.

— When the solder is not solidified, the lead of the component becomes loose.

3. Too Much Solder

a.) Appearance Characteristics: The solder surface is convex.

b.) Hazards: Waste solder and may contain defects.

c.) Possible Causes:

–The solder evacuation is too late.

4. Too Little Solder

a.) Appearance Characteristics: The soldering area is less than 80% of the pad, and the solder does not form a smooth transition surface.

b.) Hazards: Insufficient mechanical strength.

c.) Possible Causes:

— The solder fluidity is poor or the solder is withdrawn too early.

— Insufficient flux.

— The welding time is too short.

5. Rosin Welding

a.) Appearance Characteristics: Rosin slag is contained in the weld.

b.) Hazards: Insufficient strength, poor continuity, and possibly off and on.

c.) Possible Causes:

— Too many welders or have failed.

— Insufficient welding time and insufficient heating.

— The surface oxide film is not removed.

6. Overheating

a.) Appearance Characteristics: The solder joints are white, without metallic luster, and the surface is rough.

b.) Hazards: The pad is easy to peel off and the strength is reduced.

c.) Possible Causes:

-The power of the soldering iron is too large and the heating time is too long.

7. Cold Welding

a.) Appearance Characteristics: The surface becomes tofu-like particles, and sometimes there may be cracks.

b.) Hazards: The strength is low and the conductivity is not good.

c.) Possible Causes:

–There is shaking before the solder has solidified.

8. Poor Infiltration

a.) Appearance Characteristics: The contact between the solder and the soldering interface is too large and not smooth.

b.) Hazards: The intensity is low, and it is blocked or on and off from time to time.

c.) Possible Causes:

— The weldment is not cleaned up.

— Insufficient flux or poor quality.

— The weldment is not fully heated.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2023 - XPCB Limited All Right Reserve