In today’s competitive electronics industry, efficiency and reliability are paramount. XPCB’s turnkey Printed Circuit Board Assembly (PCBA) services offer a one-stop solution to streamline your production process, ensuring quality, cost-effectiveness, and faster time-to-market. This blog explores how XPCB’s comprehensive services can transform your manufacturing journey and why they are the ideal partner for your PCB needs.

What Sets XPCB Apart?

XPCB stands out in the PCB industry due to its commitment to delivering excellence at every stage of the PCBA process. With years of experience and a robust infrastructure, XPCB is equipped to handle projects of varying complexities and scales. Here are some core strengths:

- End-to-End Solutions From design assistance and component sourcing to assembly and testing, XPCB manages the entire process, eliminating the need for multiple vendors.

- Global Supply Chain XPCB leverages an extensive supply chain network to procure high-quality components at competitive prices, ensuring your projects stay on budget.

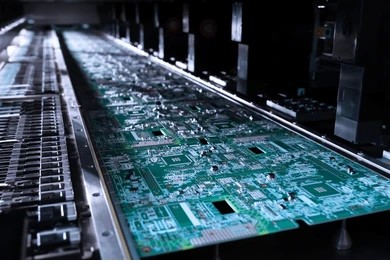

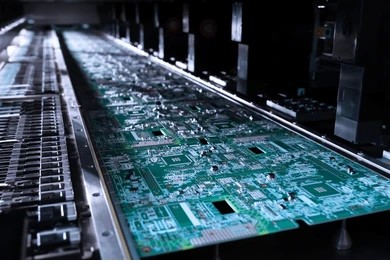

- State-of-the-Art Technology Advanced machinery and cutting-edge techniques, such as Surface Mount Technology (SMT) and Automated Optical Inspection (AOI), guarantee precision and reliability.

- Customizable Services XPCB’s flexible approach allows customization to meet your specific requirements, whether it’s a prototype or mass production.

The Turnkey PCBA Process at XPCB

XPCB’s turnkey PCBA services cover every aspect of the production cycle, ensuring seamless execution from concept to delivery. Here’s an overview of the process:

- Design Review and Optimization XPCB begins by reviewing your design files, such as Gerber files, to identify potential issues and optimize for manufacturing. Design for Manufacturing (DFM) recommendations help improve efficiency and reduce costs.

- Component Sourcing With access to a global network of trusted suppliers, XPCB procures components that meet your specifications. Rigorous inspection ensures the authenticity and quality of each part.

- PCB Fabrication High-quality PCB fabrication lays the foundation for a successful assembly. XPCB adheres to industry standards and uses advanced techniques to manufacture boards that meet your design’s exact requirements.

- SMT and Through-Hole Assembly XPCB employs advanced SMT machines for precise component placement and reflow soldering. For designs requiring through-hole components, XPCB’s skilled technicians ensure reliable manual assembly.

- Quality Assurance and Testing Quality is integral to XPCB’s process. Comprehensive testing, including AOI, X-ray inspection, and functional testing, ensures your boards are defect-free and perform as intended.

- Packaging and Delivery After assembly and testing, XPCB securely packages your PCBs and arranges for timely delivery. Custom packaging options are available to meet specific branding or logistical needs.

Why Choose XPCB for Turnkey PCBA Services?

XPCB’s turnkey services provide several advantages, making them the preferred partner for businesses seeking streamlined PCB production:

- Reduced Lead Times By consolidating all production stages under one roof, XPCB minimizes delays and accelerates time-to-market.

- Cost Savings Leveraging economies of scale and an efficient supply chain, XPCB offers competitive pricing without compromising quality.

- Single Point of Contact Managing multiple vendors can be challenging. With XPCB, you have a single point of contact, simplifying communication and coordination.

- Scalable Solutions Whether you need a small batch for prototyping or high-volume production, XPCB’s services are scalable to your needs.

- Unmatched Quality Adhering to ISO 9001 and IPC standards, XPCB ensures every product meets the highest quality benchmarks.

Applications of XPCB’s Turnkey Services

XPCB’s turnkey PCBA services cater to a wide range of industries, including:

- Consumer Electronics: Smartphones, smart home devices, and wearables.

- Automotive: Infotainment systems, sensors, and electric vehicle components.

- Medical Devices: Diagnostic tools, portable monitors, and imaging systems.

- Industrial Automation: Robotics, IoT devices, and control systems.

- Aerospace and Defense: Navigation equipment, communication systems, and avionics.

Partner with XPCB Limited for Your Next Project

XPCB’s turnkey PCBA services offer a seamless, efficient, and reliable solution for all your PCB production needs. By partnering with XPCB, you gain access to a team of experts dedicated to bringing your projects to life with precision and quality.

Streamline your production process, reduce costs, and accelerate time-to-market with XPCB. Contact us today to discuss your requirements and discover how we can help you achieve your goals.