- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

In the ever-evolving landscape of electronics, the demand for compact, lightweight, and versatile designs has driven a surge of innovation in Printed Circuit Board (PCB) technologies. Among these advancements, rigid-flex PCBs have emerged as a groundbreaking solution, revolutionizing various industries, from consumer electronics to aerospace and automotive. By combining the best of rigid and flexible circuits, rigid-flex PCBs offer unparalleled performance, reliability, and design versatility, making them a focal point for tech innovation.

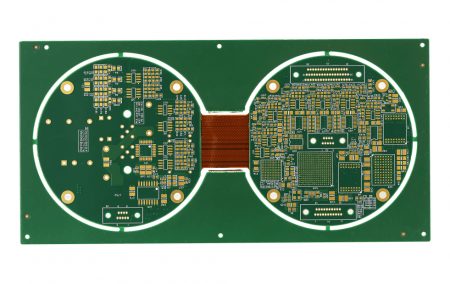

Rigid-flex PCBs are hybrid circuits that integrate rigid and flexible board technologies into a single structure. This combination allows for the construction of designs that are both durable and adaptable to complex geometries. The rigid sections provide structural support and house essential components, while the flexible parts enable bending and folding, making these PCBs ideal for compact and intricate designs.

These boards are constructed by layering multiple flexible circuit substrates with rigid boards and bonding them through a lamination process. This design approach minimizes the need for connectors and cables, reducing overall weight and size while enhancing electrical performance.

Rigid-flex PCBs have been at the forefront of technological advancements, driving innovation across several sectors:

The unique design and construction of rigid-flex PCBs offer several advantages:

Despite their numerous benefits, rigid-flex PCBs come with challenges:

Looking ahead, advancements in materials science and manufacturing technologies are poised to overcome these challenges. Innovations such as high-density interconnects (HDI) and 3D printing are expected to further enhance the capabilities of rigid-flex PCBs, opening new possibilities for their application.

Rigid-flex PCBs represent a significant leap forward in PCB technology, embodying the principles of innovation and adaptability. As industries continue to demand more compact, reliable, and high-performance electronic solutions, the role of rigid-flex PCBs will only grow. By addressing current challenges and leveraging advancements in technology, rigid-flex PCBs are set to drive the next wave of innovation, shaping the future of electronics across diverse sectors.

Whether in consumer gadgets, life-saving medical devices, or cutting-edge aerospace systems, rigid-flex PCBs are not just meeting the needs of today but paving the way for tomorrow’s technological breakthroughs. For businesses and engineers alike, embracing this versatile technology is essential to staying ahead in the ever-competitive electronics landscape.

XPCB Limited: Your One-Stop Solution for PCB Manufacturing and Assembly

XPCB Limited is your one-stop solution for all your PCB manufacturing and assembly needs. From design and prototyping to full-scale production, we offer comprehensive services under one roof. With a focus on quality, efficiency, and customer satisfaction, we make it easy for you to complete your projects with confidence. Simplify your PCB process today with XPCB Limited.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve