- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

In today’s fast-evolving technological landscape, electronics are at the forefront of innovation, driving advancements across industries such as healthcare, automotive, aerospace, and consumer electronics. At the heart of these advancements lies a crucial enabler: Printed Circuit Boards (PCBs). Among the various types of PCBs, Rigid-Flex PCBs have emerged as a game-changer, combining durability, flexibility, and performance in a single solution. Let’s explore how Rigid-Flex PCBs are reshaping modern electronics and why they are the choice for today’s electronics experts.

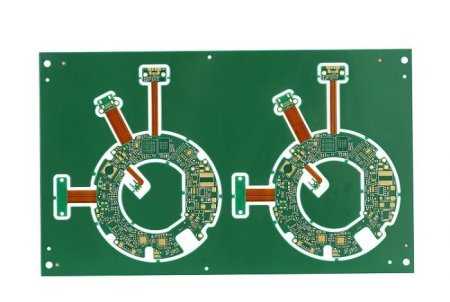

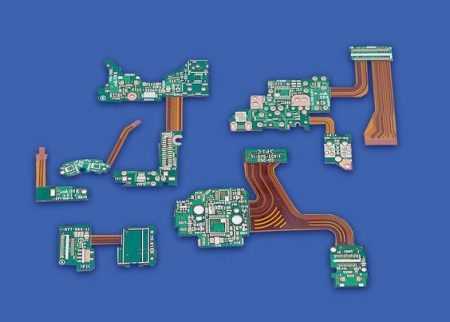

Rigid-Flex PCBs are hybrid circuit boards that integrate flexible and rigid substrates into one cohesive unit. Unlike traditional rigid PCBs, these boards can bend and twist, making them ideal for compact and complex designs. Their unique construction allows seamless integration into devices with limited space, providing both structural support and electrical interconnection.

The typical structure of a Rigid-Flex PCB involves multiple layers of flexible circuits attached to rigid boards. This design provides the flexibility to fold or flex the board during installation, reducing the need for connectors and cables while enhancing reliability and reducing assembly costs.

Rigid-Flex PCBs are a cornerstone in various industries due to their versatility and performance. Here are some of their key applications:

Despite their advantages, designing Rigid-Flex PCBs requires expertise and precision. Challenges include ensuring proper material selection, managing thermal expansion, and designing for manufacturability. However, innovations in materials and fabrication techniques are continuously expanding the possibilities of Rigid-Flex PCBs.

For instance, advancements in adhesive technology and flexible laminates have enabled the development of thinner, lighter, and more robust designs. Additionally, improved simulation tools and 3D modeling allow engineers to optimize designs before production, reducing errors and speeding up time-to-market.

As the demand for smaller, lighter, and more reliable electronic devices grows, Rigid-Flex PCBs are proving to be indispensable. They embody the perfect blend of innovation and practicality, addressing the needs of modern electronics with precision and efficiency.

For electronics experts and innovators, embracing Rigid-Flex PCB solutions means staying ahead of the curve. Whether you’re designing wearable technology, aerospace systems, or advanced medical devices, these versatile PCBs offer a pathway to enhanced performance and reliability. The future of electronics is here, and it’s flexible.

XPCB Limited: Your One-Stop Solution for PCB Manufacturing and Assembly

XPCB Limited is your one-stop solution for all your PCB manufacturing and assembly needs. From design and prototyping to full-scale production, we offer comprehensive services under one roof. With a focus on quality, efficiency, and customer satisfaction, we make it easy for you to complete your projects with confidence. Simplify your PCB process today with XPCB Limited.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve