- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

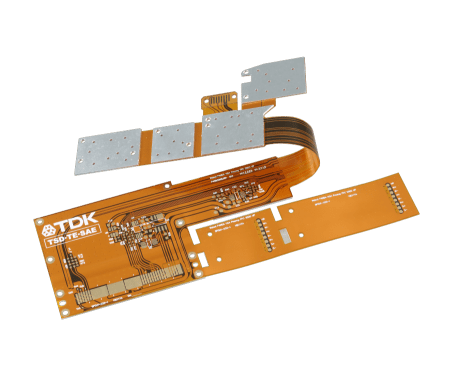

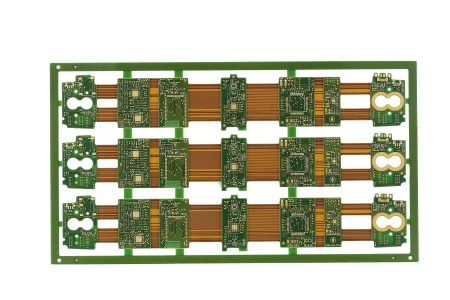

The world of electronics is evolving rapidly, with devices becoming more compact, powerful, and versatile. Central to this evolution is the role of Printed Circuit Boards (PCBs), the critical infrastructure of electronic systems. Among the various PCB technologies, rigid-flex and flex PCBs are leading the charge, enabling groundbreaking advancements across industries. This article explores the future of PCB solutions, focusing on the transformative potential of rigid-flex and flex PCBs.

Rigid-flex and flex PCBs represent a paradigm shift in PCB design, offering unique advantages that traditional rigid boards cannot match. By combining the rigidity needed for structural support with the flexibility to adapt to complex shapes, these PCBs enable engineers to create innovative, space-efficient designs.

Key characteristics that position rigid-flex and flex PCBs as the future of PCB solutions include:

Several industries are spearheading the adoption of these advanced PCBs due to their unique requirements and forward-looking approaches:

As technology advances, several trends are shaping the future of rigid-flex and flex PCBs:

While the future is bright for rigid-flex and flex PCBs, challenges remain. These include:

The continued evolution of rigid-flex and flex PCBs is unlocking new possibilities in electronics design. By embracing these technologies, manufacturers can push the boundaries of what’s possible in device performance, reliability, and functionality. Emerging innovations, such as hybrid PCB designs combining rigid-flex with advanced packaging, signal a future of even more powerful and compact electronic systems.

Rigid-flex and flex PCBs are not just solutions for today’s electronic challenges—they are the foundation for tomorrow’s technological breakthroughs. As industries prioritize miniaturization, reliability, and sustainability, these PCBs will play an increasingly central role in shaping the future of electronics. With ongoing advancements and a focus on innovation, rigid-flex and flex PCBs are poised to drive the next wave of electronic revolution.

Simplify Your PCB Journey with XPCB Limited

XPCB Limited simplifies the PCB process for you. With our quick-turnaround prototyping and turnkey PCBA services, we ensure that your projects move forward smoothly and efficiently. Trust our commitment to quality and timeliness as we help you bring your designs to life. Choose XPCB Limited for a hassle-free PCB experience.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve