- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

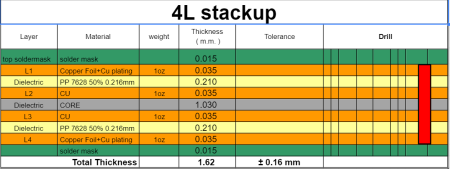

In the realm of electronics manufacturing, the printed circuit board (PCB) serves as the backbone of nearly all devices. The design and construction of a PCB are critical to the performance, reliability, and efficiency of the final product. One key aspect of PCB design is the stackup, which refers to the arrangement of conductive and non-conductive layers within the board. Understanding the importance of PCB stackup in production can significantly impact the success of electronic projects.

At the core of many electronic devices is the need for efficient signal transmission. The configuration of layers in a PCB stackup directly influences signal integrity. High-speed signals are susceptible to interference and reflections that can degrade performance. A well-designed stackup minimizes these issues by strategically placing ground planes and signal layers to provide a clear path for signal flow. By optimizing the distance between layers and controlling the impedance, designers can enhance the performance of high-speed circuits, ensuring reliable data transmission.

Electronics generate heat during operation, and managing this heat is crucial for maintaining performance and prolonging the lifespan of components. A carefully designed PCB stackup can help dissipate heat more effectively. By incorporating dedicated thermal layers or utilizing materials with high thermal conductivity, manufacturers can ensure that heat is distributed evenly across the board. This is particularly important for high-power applications, where excessive heat can lead to failure or reduced performance. Effective thermal management helps prevent overheating, ensuring that devices operate within safe temperature ranges.

Electromagnetic interference is a significant concern in electronic design, as it can disrupt the operation of sensitive components and degrade overall performance. A thoughtfully structured PCB stackup can mitigate EMI by employing shielding techniques, such as ground planes and strategic layer arrangements. By isolating sensitive signal traces and ensuring proper grounding, designers can reduce the risk of interference. This is especially critical in applications where signal integrity is paramount, such as in telecommunications and high-frequency circuits.

PCB stackup not only affects electrical performance but also influences the mechanical integrity of the board. A robust stackup can enhance the board’s ability to withstand mechanical stress, such as bending or thermal cycling. By optimizing the arrangement of layers and selecting appropriate materials, manufacturers can create PCBs that are less prone to warping or cracking. This is particularly important in portable devices or those subjected to harsh environmental conditions, where mechanical reliability is essential for long-term operation.

The complexity of the PCB stackup has direct implications for the manufacturing process. More layers can increase production difficulty and costs. A well-planned stackup can streamline the manufacturing process, ensuring that it is both efficient and cost-effective. Designers must consider the capabilities of their PCB manufacturer, including layer count, material specifications, and fabrication techniques. By aligning the stackup design with manufacturing capabilities, engineers can avoid common pitfalls that may lead to delays or increased costs.

Cost is a critical factor in any production environment. The design of the PCB stackup can significantly influence overall costs. While it may be tempting to design a complex stackup to achieve optimal performance, this can lead to higher material and manufacturing costs. A balance must be struck between performance and cost-efficiency. By carefully selecting the number of layers and materials, designers can create a stackup that meets performance requirements without exceeding budget constraints.

Ultimately, the reliability of a PCB is paramount. A well-structured stackup contributes to the long-term reliability of the board by improving its resistance to environmental factors such as humidity, temperature fluctuations, and mechanical stress. This is especially important in applications where failure can have significant consequences, such as in medical devices or aerospace systems. A reliable PCB stackup can enhance the overall lifespan of the product and reduce the likelihood of costly recalls or repairs.

The PCB stackup is a fundamental aspect of electronic design that significantly impacts the production process. From ensuring signal integrity and effective thermal management to enhancing mechanical strength and controlling costs, the stackup plays a vital role in the overall performance and reliability of the final product. As technology continues to evolve, understanding and optimizing PCB stackup will remain essential for engineers and manufacturers aiming to deliver high-quality electronic devices. By prioritizing stackup design, companies can ensure that their products meet the demands of modern technology while remaining cost-effective and reliable.

Discover a World of Possibilities with XPCB Limited

At XPCB Limited, we’re here to help you explore new horizons. Our advanced PCB manufacturing, rapid prototyping, and turnkey PCBA solutions make it easy for you to turn your ideas into reality. Trust us to deliver excellence and reliability every step of the way. Join us and experience the power of innovation with XPCB Limited by your side.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve