- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

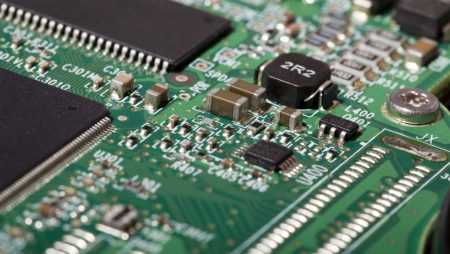

The PCB assembly technology contains through-hole assembly (THT) and Surface-Mount Technology (SMT).

A printed circuit board (PCB) assembly refers to the process in which electronic components are securely mounted on a PCB. This process involves several steps, including surface-mount technology (SMT) or through-hole assembly (THT), depending on the components used.

Surface-Mount Technology (SMT)

SMT is the most common method used in PCB assembly. It involves placing components directly onto the PCB surface, eliminating the need for long leads or holes in the board. This assembly technique offers several advantages, such as higher component density, shorter assembly time, and improved reliability.

Through-Hole Technology (THT)

THT involves inserting components through holes in the PCB, which are then soldered to secure the components in place. This technique is often used for components with larger footprints or those without SMT alternatives. THT assembly requires careful alignment and manual soldering, which adds complexity to the assembly process.

‘

Assembly Process

To assemble a PCB, the following steps are typically followed:

Quality Control

To ensure a high-quality PCB assembly, several quality control measures can be taken:

– Visual Inspection: The assembled PCB is visually inspected to ensure the correct component placement and solder joints.

– Electrical Testing: Electrical testing is performed to check the functionality and performance of the assembled PCB.

– AOI (Automated Optical Inspection): A specialized machine is used to perform automated optical inspection of the PCB, checking for defects such as missing components or solder bridges.

– X-RAY Inspection: An X-ray machine is used to inspect solder joints for defects such as voids or solder splashes.

PCB assembly is a critical step in the electronic manufacturing process. Whether using SMT or THT techniques, the assembly process involves carefully selecting and placing components on the PCB, followed by soldering and testing. Quality control measures such as visual inspection, electrical testing, and AOI and X-ray inspection are essential to ensure a reliable and functioning assembly.

What is BOM list: BOM list refers to the PCB materials required for the final specific printing of PCBA products, and the circuit board company will purchase according to the BOM list provided by the customer, and the product will be sent to the customer after the final soldering test is passed.

So far, China’s printed circuit board company, the production of PCB bare board and SMD are separated, after the printed PCB company will hand over the finished circuit board to the SMT factory, all the materials will be soldered up to be a real PCB product, so we now understand what is the importance of the BOM list used in the follow-up PCB SMD!

BOM helps in proper planning and smooth operation. A BOM is required for audits, and it helps to keep track of the parts purchased and the parts available in the inventory. It’s crucial to get exactly what you want or what is made by a particular manufacturer. If that doesn’t work, you can discuss and offer other options right away.

Factors to consider when making a BOM list are: It’s not a good idea to consider the full number you think you’ll need (50 PCB components at a time). Consider a PCB assembly, find out the type of PCB and the required components, and list the part details of only one component. Let a team of professional engineers figure out all the parts you need. Send the curated list to the customer for verification.

Simplify Your PCB Journey with XPCB LimitedXPCB Limited simplifies the PCB process for you. With our quick-turnaround prototyping and turnkey PCBA services, we ensure that your projects move forward smoothly and efficiently. Trust our commitment to quality and timeliness as we help you bring your designs to life. Choose XPCB Limited for a hassle-free PCB experience.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve