- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

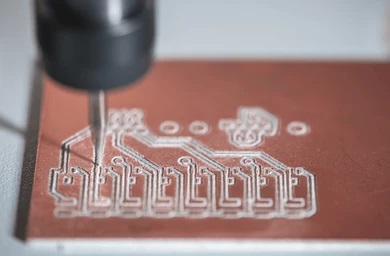

In the realm of surface mount technology (SMT) manufacturing, dispensing machines play a crucial role in the assembly process of electronic components. These machines are designed to precisely apply adhesives, solder paste, or other materials onto printed circuit boards (PCBs), ensuring secure connections and optimal performance. This blog will delve into the importance, types, working principles, advantages, applications, and future developments of dispensing machines in SMT factories.

Dispensing machines are essential in the SMT process for several reasons. Their primary function is to apply materials with high precision and in the correct quantity, which is vital for ensuring the quality of solder joints and component placements. Especially when dealing with small or intricate components, precise dispensing enhances assembly efficiency, reduces material waste, and guarantees reliable electrical connections. A well-functioning dispensing machine can significantly impact the overall production quality and yield of electronic devices.

Dispensing machines come in various types to cater to different production needs:

Manual Dispensing Machines: These are typically used for small-scale production or prototyping, operated by hand. They offer flexibility but require more operator skill and time.

Semi-Automatic Dispensing Machines: These machines provide a balance between manual and full automation, requiring some human intervention but significantly reducing labor intensity. They are suitable for mid-volume production.

Fully Automatic Dispensing Machines: Designed for high-volume production, these machines operate at high speeds and with high precision. They can automatically dispense materials onto PCBs according to predefined patterns and specifications, minimizing human error.

The working principle of dispensing machines involves several key steps:

Material Preparation: The adhesive, solder paste, or other materials are loaded into the dispensing head. This may involve heating or mixing materials as necessary to achieve optimal consistency.

Motion Control: A computer-controlled motion system guides the dispensing head along a predetermined path, ensuring accurate positioning and timing.

Dispensing Process: At designated points, the machine releases the material, creating precise dots or lines as required by the PCB design. Advanced machines can adjust the dispensing speed and volume dynamically for greater accuracy.

Dispensing machines offer numerous advantages that contribute to their widespread use in SMT factories:

Increased Efficiency: These machines can quickly apply materials, significantly boosting production speed and output.

Improved Quality: By controlling the amount of material dispensed, the risk of soldering defects is reduced, leading to higher reliability in the final product.

Cost Reduction: Less material waste combined with lower labor costs translates to significant savings in the long run.

Dispensing machines are extensively used across various sectors of the electronics industry:

PCB Assembly: They are primarily used to apply solder paste on circuit boards, preparing them for component placement.

Optoelectronic Products: In applications such as LED lighting and displays, dispensing machines are used for encapsulation and bonding.

Automotive Electronics: These machines are crucial in the assembly of automotive control systems and sensors, where reliability and durability are paramount.

Medical Devices: In the medical field, dispensing machines help ensure secure connections between electronic components in devices such as diagnostic equipment and monitoring systems.

As technology evolves, dispensing machines are also advancing. New techniques such as laser dispensing and 3D printing are beginning to find their way into the dispensing arena, offering new levels of precision and complexity. The ongoing trend toward miniaturization in electronic devices is driving the development of more compact and flexible dispensing solutions. Additionally, the integration of smart technology and automation will make dispensing machines even more adaptable and efficient, capable of meeting rapidly changing market demands.

Dispensing machines are integral to the operation of SMT factories, enhancing the efficiency, quality, and cost-effectiveness of electronic assembly processes. Their ability to apply materials with precision significantly impacts the reliability and performance of electronic devices. As the electronics industry continues to innovate, dispensing machines will evolve alongside it, ensuring they remain a vital component of modern manufacturing practices. The future holds exciting possibilities for these machines, with advancements poised to further revolutionize the way electronic components are assembled.

Simplify Your PCB Journey with XPCB LimitedXPCB Limited simplifies the PCB process for you. With our quick-turnaround prototyping and turnkey PCBA services, we ensure that your projects move forward smoothly and efficiently. Trust our commitment to quality and timeliness as we help you bring your designs to life. Choose XPCB Limited for a hassle-free PCB experience.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve