- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

With increased environmental awareness, automotive products are slowly converted from the original motorized to electric, thereby reducing gas emission pollution. As this demand continues to increase, so does the demand for charging stations.

Now many first-tier cities’ electric vehicles are quietly entering people’s lives. Now many factories or houses can be seen around the charging pile, and the charging pile circuit board has also become the object of chasing the baton.

Because the circuit board of the charging pile needs to meet the high current and high voltage during operation, the general conventional thin board cannot withstand it at all. Although all PCB board materials are made of copper, there are certain differences in grades.

The ordinary plate is below TG140, and the base material used in the production of the circuit board of the new energy charging pile needs to be above TG150, which is a high TG material. The data shows that the higher the grade parameters, the better the quality of the panels.

It is not allowed to defect the line, residual copper on the edge of the line, yellow impedance on the edge of the hole, etc., And manufacturers of charging pile circuit boards also need to implement IPC-III standards to prevent products that do not reach from being eliminated in time.

The circuit board of the new energy charging pile is used for large models, and the current amount is not comparable to that of ordinary charging piles.

The output of the DC charging pile is composed of 9 wires, including “ground wire PE, DC power line DC+ and DE-, communication line S+ and S-, low-voltage auxiliary line A+ and A-, charging connection confirmation line CC1 and CC2”. The DC charging pile is to complete the charging of electric vehicles by providing 9 wires.

An important link in the principle of the charging pile is “interface connection confirmation”, after the DC charging pile charging gun is inserted into the electric vehicle charger port, the charging pile monitoring point will detect the voltage when the voltage of 4V is detected, the charging pile will judge that the charging interface is connected successfully, and lock the electronic lock in the charging gun to avoid falling off.

(3) DC charging pile self-test:

(3) DC charging pile self-test:

When the charger port is successfully connected, the charging pile closes the K3 and K4 switches. So that the low-voltage auxiliary circuit is turned on to supply power to the electric vehicle control device, and the electric vehicle will judge whether the interface is connected according to the low voltage of the monitoring point after receiving the power supply.

If the voltage is 6V, the car will periodically send a handshake message, and then close the K1 and K2 switches for insulation monitoring to detect the insulation performance of the DC line and ensure the safety of the charging process. After the insulation test, the bleed-off circuit is connected to bleed the energy, and the K1 and K2 switches are disconnected.

Your Trusted Partner for PCB Success: XPCB Limited

Let XPCB Limited be your guide to PCB success. Our comprehensive PCB manufacturing, rapid prototyping, and turnkey PCBA services are designed to meet your needs with ease. Count on us to deliver reliable solutions that exceed your expectations. With XPCB Limited, your journey to PCB excellence starts here.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

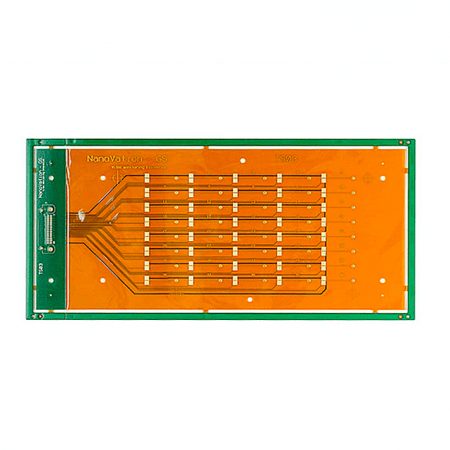

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve