- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

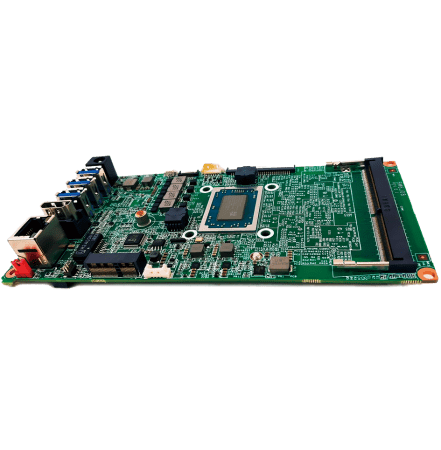

As the year draws to a close, businesses across various industries ramp up production to meet the holiday season demand. For Chinese PCB (Printed Circuit Board) manufacturers, this period is particularly challenging, with a surge in demand for PCBA (Printed Circuit Board Assembly) and SMT (Surface-Mount Technology) services. To stay competitive and ensure timely deliveries, PCB manufacturers must navigate a complex set of challenges, including tighter deadlines, increased order volumes, and heightened expectations for quality and cost-efficiency. In this blog, we will explore how Chinese PCB manufacturers manage the year-end surge and what strategies they employ to meet the growing demands of the PCBA and SMT markets.

The demand for PCBs, especially those used in consumer electronics, automotive devices, and IoT (Internet of Things) products, tends to spike as the year-end approaches. For many industries, this is the final push before the holiday season, with companies racing to complete orders to ensure products reach the market in time for the shopping frenzy. This creates a seasonal rush for PCB manufacturers who not only need to produce high-quality PCBs but also provide quick-turnaround PCBA and SMT services to meet the increasing order volumes.

This surge is exacerbated by the rising complexity of modern electronics, which require increasingly sophisticated PCBs and more advanced assembly techniques. As a result, manufacturers must ensure that they can deliver both high-quality products and fast turnarounds without compromising on either.

With the growing demand for electronics in sectors like consumer devices, automotive, and medical technologies, Chinese PCB manufacturers often face an influx of last-minute orders. These orders often come with tight deadlines, creating production bottlenecks and increasing pressure on manufacturers to meet delivery dates. In addition, many customers expect flexible, customized solutions, which further complicates scheduling.

As PCB production ramps up toward the end of the year, material shortages are a common challenge. Raw materials such as copper, resins, and solder paste, as well as specialized components used in PCBA and SMT processes, may be in high demand and short supply. Shipping delays and supply chain disruptions—especially those related to international logistics—can cause further delays, making it crucial for manufacturers to manage these challenges effectively.

Many Chinese PCB factories also face labor shortages toward the end of the year. With the Chinese New Year approaching, many workers take time off or leave for the holidays, leading to reduced capacity. Managing labor during this period becomes a delicate balancing act, as manufacturers need to ensure they have enough skilled workers to maintain production efficiency while still keeping costs in check.

With increased pressure to meet tight deadlines, maintaining consistent product quality can become a challenge. The risk of quality defects rises, especially when manufacturers are working at full capacity. Ensuring that all PCBA and SMT assemblies meet customer specifications requires rigorous quality control processes and thorough testing.

To successfully manage the increased demand during the year-end surge, Chinese PCB manufacturers employ a variety of strategies that help them maintain production efficiency, quality, and customer satisfaction.

One of the first steps in managing the year-end surge is optimizing the production schedule. By analyzing customer orders in advance, manufacturers can allocate resources more effectively, prioritize high-value or urgent orders, and stagger production runs to avoid bottlenecks. This approach ensures that critical orders are completed on time without sacrificing the quality of less time-sensitive products.

Additionally, flexible scheduling allows manufacturers to accommodate a mix of small batch orders and large-scale production, which is common during the holiday rush. Some manufacturers even employ automated production scheduling systems to streamline the process.

To mitigate material shortages, Chinese PCB manufacturers often strengthen relationships with suppliers, ensuring priority access to raw materials and components. Establishing long-term partnerships and early ordering can help secure necessary materials before the supply chain becomes overwhelmed during the year-end rush. Manufacturers may also explore alternative materials or suppliers to reduce dependency on single sources and ensure timely deliveries.

The increasing demand for PCBA and SMT services has led many Chinese PCB manufacturers to offer comprehensive, one-stop solutions. This model not only streamlines the production process but also reduces the time needed for clients to source various components and services. A one-stop solution typically includes PCB design, prototyping, assembly, and testing, all provided under one roof.

By offering a complete range of services, manufacturers are able to shorten the lead time and deliver faster to customers, which is particularly crucial during peak seasons like year-end. Moreover, clients appreciate the convenience of working with a single vendor, as it minimizes risks associated with miscommunication or delays between different service providers.

During the peak season, manufacturers often expand their production capacity by increasing workforce size or shifting to multiple shifts to boost output. In some cases, temporary workers or external contractors are brought in to handle increased demand. Additionally, maintaining a flexible workforce that can quickly adapt to different tasks or production lines helps keep operations smooth.

In some cases, manufacturers might also invest in automated assembly lines or robotics for high-volume tasks like SMT, allowing them to meet the demand without overburdening their human workforce.

Despite the rush to meet deadlines, maintaining high-quality standards is essential. Chinese PCB manufacturers typically implement multi-layered quality control processes, such as automated visual inspection, X-ray analysis, and functional testing, to ensure that the final product meets customer specifications. By integrating these quality assurance techniques into every stage of the production process, manufacturers can minimize the risk of defects and ensure timely delivery of high-quality products.

Managing the year-end surge in demand for PCBA and SMT services is no easy task for Chinese PCB manufacturers. With tight deadlines, labor and material shortages, and increasing customer expectations, it requires careful planning, strategic resource allocation, and effective communication across the supply chain. By optimizing production schedules, building strong supplier relationships, leveraging one-stop solutions, expanding capacity, and maintaining rigorous quality control, manufacturers can successfully navigate the holiday rush and continue to deliver high-quality products on time. As the demand for electronics continues to rise, these strategies will become even more critical in helping Chinese PCB manufacturers remain competitive in the global market.

Simplify Your PCB Journey with XPCB Limited

XPCB Limited simplifies the PCB process for you. With our quick-turnaround prototyping and turnkey PCBA services, we ensure that your projects move forward smoothly and efficiently. Trust our commitment to quality and timeliness as we help you bring your designs to life. Choose XPCB Limited for a hassle-free PCB experience.

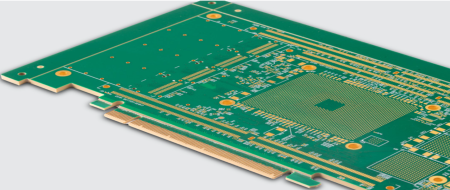

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve