- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

Menu

In theory, there can be three options.

Option I

1 power layer, 1 ground layer and 2 signal layers are arranged in this way: TOP (signal layer), L2 (ground layer), L3 (power layer), BOT (signal layer).

Option II

One power layer, one ground layer and two signal layers are arranged in this way: TOP (power layer), L2 (signal layer), L3 (signal layer), BOT (ground layer).

Option III

1 power layer, 1 ground layer and 2 signal layers are arranged in this way: TOP (signal layer), L2 (power layer), L3 (ground layer), BOT (signal layer).

Option I

The main laminated design scheme of the 4 layer flexible PCB has a ground plane under the component surface, and the key signal is preferably placed on the TOP layer; as for the layer thickness setting, the following suggestions are made: the impedance control core board (GND to POWER) should not be too thick so as to reduce the distributed impedance of the power supply and ground plane; ensure the decoupling effect of the power plane.

Option II

These solutions are mainly to achieve a certain shielding effect, placing the power supply and ground plane on the TOP and BOTTOM layer. While following defects may occur if hoping to get perfect shielding effect by this solution.

Solution 2 has a limited range of use. But in individual boards, Solution 2 is the best layer setting solution.

Option III

This scheme is similar to scheme 1, and is suitable for the case where the main components are laid out in the BOTTOM layout or the bottom layer of key signals.

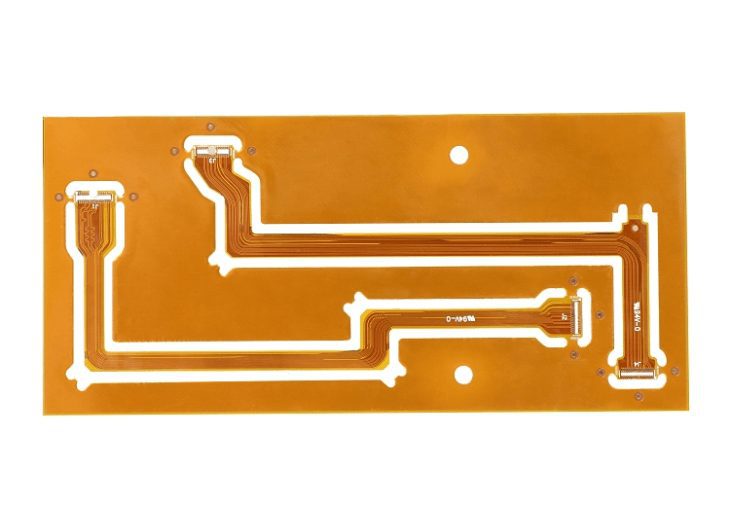

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2023 - XPCB Limited All Right Reserve