- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

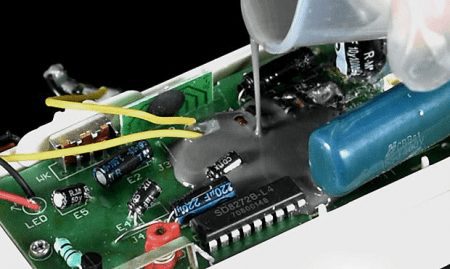

The title refers to the printed circuit board, also known as the printed wire board, which is the provider of electrical connections for electronic components. In the electronic industry is very common, and three anti-glue in the application is also very widespread. There is no PCB board three glue this type of adhesive, is actually on the PCB coated with a layer of three glue.

Moisture is the most common and destructive factor in PCB board. Excessive moisture can significantly reduce insulation resistance between conductors, accelerate rapid decomposition, reduce Q values, and corrode conductors. It often happens that the metal part of PCB becomes verdigris, which is caused by the chemical reaction of copper, water vapor and oxygen.

Because the PCB board that has used three anti-glue is not only waterproof, moisture-proof, and dust-proof but also has the properties of cold and heat shock resistance, aging resistance, radiation resistance, salt spray resistance, ozone corrosion resistance, vibration resistance, good flexibility, strong adhesion and so on.

Coating the PCB board and parts with triple glue can reduce or eliminate the deterioration of electronic operation performance when it is affected by adverse factors of the operating environment.

Due to the different application environments of different terminal products, the performance requirements of the three anti-glue products will be emphasized. Household appliances such as refrigerators, washing machines and water heaters require high moisture resistance, while outdoor fans and street lamps require excellent anti-fog performance.

As the “protector” of PCB circuit board, three anti – glue shows its professionalism. For the selection of such adhesive products with professional requirements, it is natural to choose professional and regular brands and use them more confidently. For example, Cosmol Cosmol is specialized in the research and development and production of triple rubber. It is a provider of customized solutions according to different needs.

Electronic products are very afraid of being damaged if they need to be used in a harsh environment. It is strongly recommended to coat THE PCB with tri-glue to form a good protective coating. Moistureproof anticorrosion shockproof, protection function everything. Now, you know why you need to put triple glue on the PCB board. If you need it, don’t act now!

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve