- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

Menu

Precautions for SMT Chip Processing

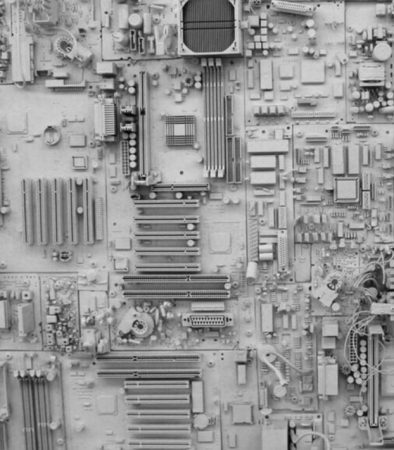

SMT chip processing is a high-precision electronic processing process. The functions of electronic products are more complete. The integrated circuits (ICs) used have no perforated components, especially large-scale and highly integrated ICs, but have to use surface mount elements. Strictly speaking, a complete PCB circuit board is not a simple board, it is a collection of high-tech. From aircrafts flying hundreds of thousands of light-years away, small remote controllers for home use, chips as small as 5mm, and then integrated into circuit boards through SMT chip processing and DIP plug-in post-soldering, in order to achieve various such a function. Next, I will take you to understand the matters needing attention in the chip processing of the SM chip processing factory.

1. In SMT chip processing, electrolytic capacitors cannot contact heating elements, such as transformers, thermistors, high-power resistors and radiators.

2. There shall be no copper foil (except grounding) and component or structural drawing requirements within the radius of 5mm of the screw hole. In practice, the pad size (diameter) of through-hole mounting components is generally twice that of the hole.

3. The distance between the center of the backing plate processed by SMT is less than 2.5mm, and there should be a silk screen oil bag around the adjacent backing plate, and the width of the silk screen oil is 0.2mm. After passing through the tin furnace, the solder pad should be opened with tin, and the direction should be the same as that of the tinThe direction is opposite to the direction in which the tin passes.

4. The minimum distance between the copper foil of the circuit board and the edge of the board is 0.5mm, the minimum distance between the SMD components and the edge of the board is 5.0mm, the minimum distance between the pad and the edge of the board is 4.0mm, and the distance between the copper foils of the single board is 4.0mm. The minimum gap is 0.3mm, and the minimum gap between double-board copper foils is 0.2mm.

5. Generally in the design of large-area printed circuit boards, in order to prevent the printed circuit board from bending when passing through the tin furnace, we will leave a gap of 5mm to 10mm in the middle of the printed circuit board, so as to avoid placing components, so that add slats to prevent bending when going through the tin oven.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2023 - XPCB Limited All Right Reserve