- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

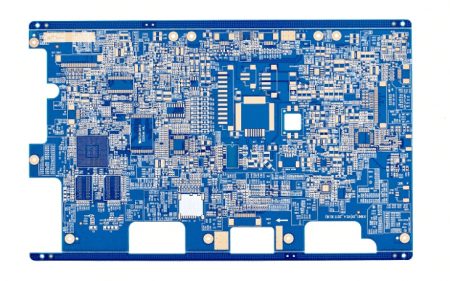

In today’s rapidly evolving electronics industry, the demand for smaller, faster, and more reliable devices has never been higher. Central to this innovation is the development of High-Density Interconnect (HDI) printed circuit boards (PCBs). These advanced PCBs enable engineers to create compact, high-performance electronic devices, making them a cornerstone of modern technology. This blog explores the comprehensive solutions available for complex PCB manufacturing and PCB assembly (PCBA), from HDI design to the final product.

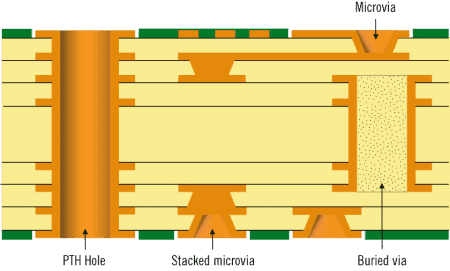

HDI PCBs have transformed the landscape of electronics by allowing greater functionality within reduced space. They are characterized by finer lines and spaces, smaller vias, and higher connection pad densities compared to traditional PCBs. This enables designers to integrate more components, improving overall device capabilities while maintaining a compact form factor.

Key Features of HDI PCBs:

Manufacturing HDI PCBs involves intricate processes that demand precision and expertise. Leading providers offer end-to-end services to meet the unique requirements of modern electronics. Here’s a breakdown of the key services involved:

Effective PCB manufacturing begins with robust design support. DFM services help optimize designs for efficient production while minimizing errors. This includes material selection, advanced stack-up configurations, and precise drilling strategies tailored to HDI requirements.

Fabrication involves the physical creation of the PCB, utilizing advanced techniques to meet exact specifications. HDI fabrication processes include laser drilling for microvias, precise etching for fine-line routing, and lamination of multiple layers to achieve the desired density.

PCBA integrates components onto the fabricated PCB. This stage includes Surface Mount Technology (SMT) and Through-Hole Technology (THT) assembly. Accurate component placement and soldering are crucial to ensuring functionality and reliability.

Comprehensive testing ensures the final product meets performance standards. Techniques such as Automated Optical Inspection (AOI), X-ray imaging, and electrical testing validate the integrity and reliability of the PCB.

Turnkey solutions streamline the process by managing everything from component sourcing to final assembly. This reduces time-to-market and ensures seamless integration of all stages.

Several companies specialize in HDI PCB manufacturing and assembly, offering a complete range of services. These providers cater to industries ranging from consumer electronics and automotive to healthcare and aerospace. Some of the top names include:

As the demand for compact and high-performance devices continues to grow, the importance of HDI PCBs and advanced manufacturing services cannot be overstated. By leveraging comprehensive solutions, businesses can achieve faster development cycles, higher product quality, and better market competitiveness.

Whether you’re designing the next breakthrough device or refining an existing product, partnering with experienced PCB manufacturers and PCBA providers ensures you’ll have the technology and expertise to bring your vision to life.

XPCB Limited: Advanced PCB Manufacturing to Simplify Your Journey

Navigating the complexities of PCB production has never been easier. XPCB Limited combines advanced PCB manufacturing technology with streamlined processes to offer solutions that meet your exact requirements. From prototypes to mass production, we are committed to quality, speed, and affordability. Trust XPCB Limited to make your PCB journey simple and successful.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve