- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

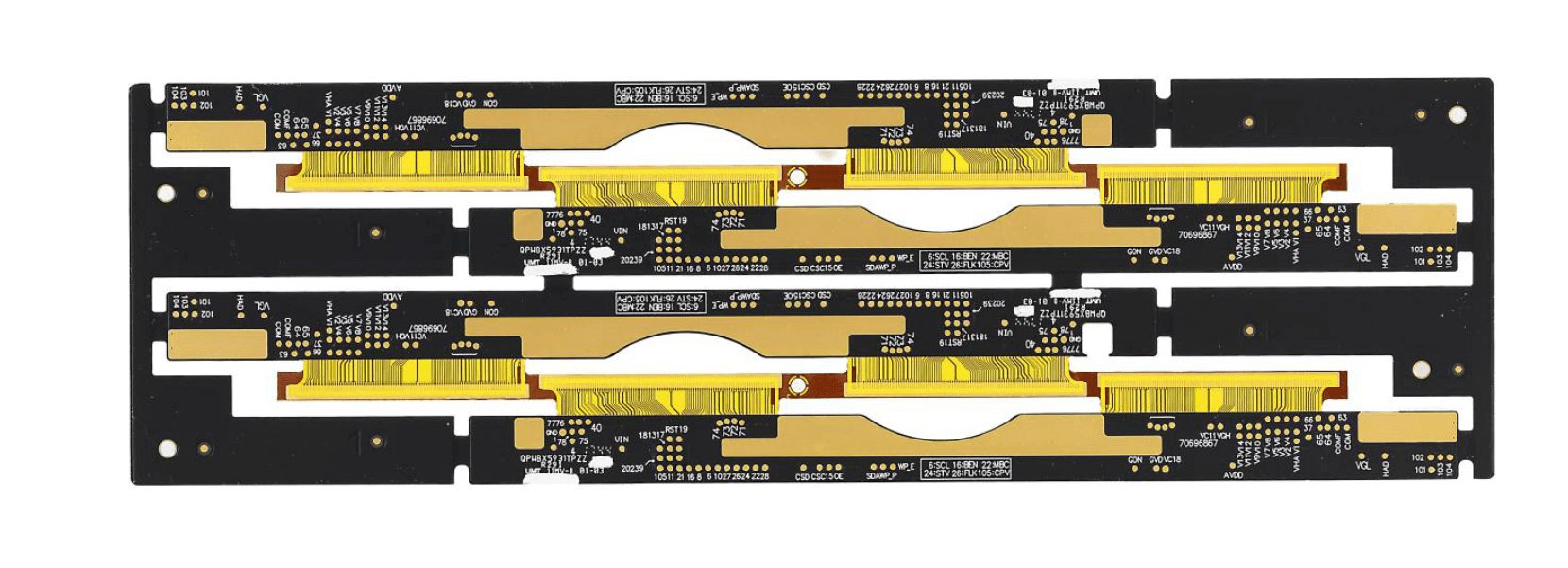

HDI circuit board refers to the microvia (Microvia) with the aperture below 6mil, the hole ring diameter (HolePad) below 0.25mm, and the contact density at 130 points/square inch Above, the wiring density is above 117 inches/square inch, and its line width/spacing is below 3mil/3mil.

Generally speaking, HDI circuit boards have the following advantages:

HDI technology is a critical component of most of today’s innovative modern technologies. The miniaturization of digital parts consisting of PCBs has actually allowed suppliers to generate smaller sized, much more cost-efficient devices without compromising efficiency or reliability. Here are simply a few of the sectors that make use of HDI PCBs, in addition to just how they utilize them:

Consumer Electronic devices: Computers made use of to take up whole rooms, and now, thanks partly to HDI modern technology, tools as tiny as smartwatches are basically miniature desktop computers. You can find HDI boards in laptop computers, smartphones, tablets and also wearables, as well as other consumer electronics like digital video cameras as well as GENERAL PRACTITIONERS tools. HDI PCBs play a vital function in enabling the daily consumer to gain access to these powerful innovations. They’re also essential parts of IoT devices for the house, including smart thermostats, fridges as well as the many various other connected gadgets readily available. As these wise gadgets become more typical, so do HDI boards.

Communications: Along with mobile phones and laptops, HDI PCBs likewise show up in the tools that allows those tools to function, such as routers, switches, components and semiconductors. Anytime you use electronic interactions, a digital device or a tool that uses radio waves, there’s a great chance you’re using an HDI board. Digital video and also audio equipment also frequently uses HDI innovation. These boards are present in devices utilized for individual interaction, in addition to the networks used by organisations.

Automotive and also Aerospace: HDI PCBs permit suppliers to fit even more abilities right into smaller sized areas and also gadgets that consider much less. This is especially beneficial in the vehicle and also aerospace industries, where lower weight can mean much more efficient procedure. Like practically everything else, cars are becoming much more connected and computerized. Today’s autos have around 50 microprocessors on board that play a role in engine controls, diagnostics, security features and also various other benefits. Numerous new features such as onboard WiFi and GENERAL PRACTITIONERS, rearview electronic cameras as well as backup sensors count on HDI PCBs. As vehicle innovation continues to breakthrough, HDI technology will likely play a significantly important role.

Medical Industry: Advanced digital medical devices– consisting of some types of tools for monitoring, imaging, surgeries, lab analysis as well as other uses– might integrate HDI boards. The high-density innovation promotes enhanced efficiency and smaller sized, much more cost-effective devices, possibly improving the precision of surveillance as well as medical screening.

Industrial Automation: Industrial equipment is additionally becoming extra electronic, and IoT tools are becoming a lot more typical in manufacturing, warehousing and also other commercial settings. Many of this innovative tools uses HDI innovation. Today, organisations use digital tools to track supply as well as screen tools efficiency. Increasingly, machinery consists of clever sensing units that collect use information and also link to the web to interact with other wise gadgets, in addition to pass on information to administration and help optimize operations.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve