- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

Menu

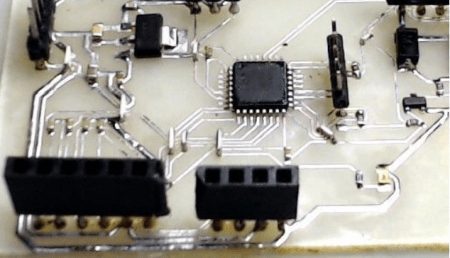

Some SMD components are very small, and it is very inconvenient to use ordinary multimeter test pens to test and repair. First, it is easy to cause a short circuit, and second, it is inconvenient to contact the metal parts of the component pins on the circuit board coated with the insulating coating. Here is a simple method that will bring a lot of convenience to the detection.

Take two smallest sewing needles and place them close to the multimeter pen, then take a thin copper wire from a multi-strand cable, use the thin copper wire to tie the test pen and sewing needle together, and then use solder to solder them firmly. . In this way, there is no risk of short circuit when testing those SMT components with a test pen with a small needle tip, and the needle tip can pierce the insulating coating and directly hit the key parts, so there is no need to bother to scrape those membranes.

In printed circuit board maintenance, if there is a short circuit of the public power supply, it is often a big problem, because many devices share the same power supply, and each device using this power supply is suspected of being short-circuited.

If there are not many components on the board, the short-circuit point can eventually be found by using the method of “hoeing the ground”; if there are too many components, it will depend on luck whether the “hoeing the ground” can reach the situation. A more effective method is recommended here. Using this method, you can get twice the result with half the effort, and you can often find the fault point quickly.

It is necessary to have a power supply with adjustable voltage and current, voltage 0-30V, current 0-3A, this kind of power supply is not expensive. Adjust the open circuit voltage to the power supply voltage level of the device, first adjust the current to the minimum, and add this voltage to the power supply voltage point of the circuit, such as the 5V and 0V terminals of the 74 series chip, and gradually increase the current depending on the degree of short circuit.

Touch the device with your hand. When you touch a device with obvious heat, this is often a damaged component, which can be removed for further measurement and confirmation. Of course, the voltage must not exceed the working voltage of the device during operation, and it cannot be reversed, otherwise other good devices will be burned.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2023 - XPCB Limited All Right Reserve