- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

Menu

The PCB manufacturing process is a crucial step in creating printed circuit boards (PCBs). It involves various steps to ensure that the PCB meets the desired specifications. However, this process can be time-consuming and prone to errors, leading to inefficiencies. To streamline the PCB manufacturing process, it is essential to implement effective techniques and strategies. This document outlines some strategies that can help optimize the manufacturing process.

DFM is a crucial step in designing PCBs. It involves analyzing the design to ensure that it can be manufactured cost-effectively and within the specified constraints. By incorporating DFM principles, engineers can identify and address potential manufacturing issues during the design phase. This can help minimize rework and delays during production.

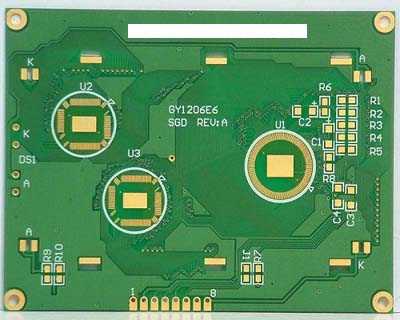

Standardizing PCB designs can streamline the manufacturing process. By adopting common design formats, such as Gerber files and IPC-D-356, manufacturers can automate many of their processes, reducing errors and streamlining production. Standardization also enables effective communication between designers and manufacturers, ensuring accurate and timely transfer of design information.

Utilizing a PCB design software can enhance the PCB manufacturing process. These programs provide advanced features and tools that aid in the design, layout, and documentation of the PCB. By automating certain tasks, such as component placement and routing, designers can save time and minimize errors. Additionally, PCB design software often includes DFM checks, which further streamline the design process.

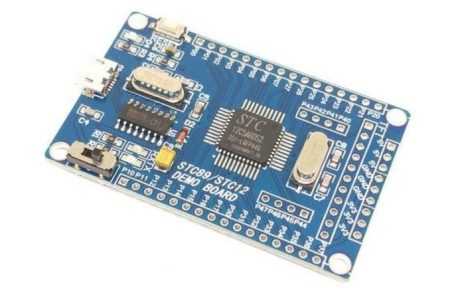

Efficient PCB Fabrication

Streamlining the assembly process is essential for efficient PCB manufacturing. By optimizing the assembly process, manufacturers can improve throughput and minimize errors. Some strategies to consider include:

– Automated Soldering: Implementing automated soldering systems can reduce the need for manual labor and improve accuracy.

– Assembly Line Configuration: Optimizing the arrangement of assembly equipment can minimize downtime and increase productivity.

– Lean Manufacturing Principles: Applying lean manufacturing principles can help reduce waste and streamline the assembly process.

Conducting regular quality control inspections is essential to ensure the quality and reliability of PCBs during the manufacturing process. By implementing robust inspection procedures, manufacturers can identify and address issues early on, reducing rework and defects. Quality control inspections can include visual inspections, electrical testing, and component analysis.

Streamlining the PCB manufacturing process requires a combination of effective strategies and techniques. By incorporating DFM principles, standardizing designs, using PCB design software, implementing automated manufacturing systems, optimizing assembly processes, and conducting regular quality control inspections, manufacturers can significantly enhance efficiency and productivity. These strategies not only improve product quality but also reduce costs and lead times, ultimately leading to successful PCB manufacturing.

Make Your PCB Dreams a Reality with XPCB Limited

XPCB Limited is your go-to partner for turning your PCB dreams into reality. Our streamlined PCB manufacturing process, combined with quick-turnaround prototyping and turnkey PCBA services, ensures that your projects come to life with ease. Trust in our expertise and dedication to quality as we help you achieve your PCB goals. Join us and experience the difference with XPCB Limited.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2023 - XPCB Limited All Right Reserve