- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

Menu

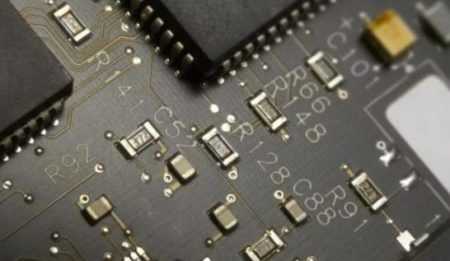

PCB application field is very wide, large to the aviation military industry to household electronics, are inseparable from its figure, the use of copper to connect the components on the circuit board to play a conductive effect. If the circuit board is exposed to air for a long time, not only will the circuit board oxidize but it will lose solderability due to corrosion.

So it is necessary to use special technology to protect the circuit board, PCB electroplating process operation flow:

Acid → full plate copper → pattern transfer→ acid degreasing→ secondary countercurrent rinsing→ micro-etching→ secondary acid → tin plating→ secondary countercurrent rinsing→ acid → pattern copper plating→ secondary countercurrent rinsing→ nickel plating→ secondary water washing→ citric acid → gold plating→ recovery→ 2-3 pure water washing→ drying.

There are three kinds of common PCB electroplating technology: oxide film, organic painting, and electroplating technology, among which most PCB manufacturers will choose electroplating technology, of course, there are also factories that choose the other two technologies.

So what are the differences between these three PCB electroplating processes?

6. Some brown films are produced in the chrome plating layer, mainly caused by insufficient sulfate, and the temperature of the bath solution is too low or interfered by impurities (such as Cl-), which will produce brown films in the chromium plating.

7. The phenomenon of coating peeling after nickel plating and chromium plating is due to poor pre-plating, which is related to the condition of the plating solution and the phenomenon of double nickel.

8. Two problems that need to be paid attention to in bright nickel plating, industrial raw materials are impure, such as zinc and nitrate, nickel sulfate contains copper, and anode nickel plate contains iron and other impurities. And copper and chromium brought in from the product or hanging gear that is contaminated in the production process, improperly cleaned, and so on. Decomposition products of organic additives. These are harmful impurities of bright nickel plating, which should be eliminated with care.

Your Trusted Partner for PCB Success: XPCB Limited

Let XPCB Limited be your guide to PCB success. Our comprehensive PCB manufacturing, rapid prototyping, and turnkey PCBA services are designed to meet your needs with ease. Count on us to deliver reliable solutions that exceed your expectations. With XPCB Limited, your journey to PCB excellence starts here.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2023 - XPCB Limited All Right Reserve