- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

Menu

Electro- and electroless plating of tin, nickel, gold, and solder are common surface treatments for flexible circuits. Solder plating by a hot-air leveler could be a low-cost solution. However, it entails severe high-temperature process conditions, and the poor uniformity of the solder is not acceptable for several applications.

Several new surface finishing technologies have been developed to satisfy the requirements of new termination technologies. Soft nickel/gold plating is the major process for the wire-bonding and flip-chip bonding processes. A tin plating is also available for flip-chip bonding. A hard nickel/gold plating is applied for the fine pitch pads of ACF termination (Anisotropic Conductive Film) and insertion parts of the FFC connectors. Tin- and lead-free solder plating will be an alternative treatment to traditional solder plating. OSP (Organic Surface Protection) will be a low-cost solution for next-generation soldering eliminating the lead components.

Prior to the surface treatment for the opened conductors, a suitable cleaning process is required to have good plating performances. Sometimes, it needs a strong chemical with mechanical brushing to remove the tough residues and oxidation on the copper surface made by previous processes. Strong alkaline solutions should be eliminated as the cleaning reagents. Several adhesive resins and photo-imageable coverlays have been attacked seriously and they cause de-lamination of the coverlay.

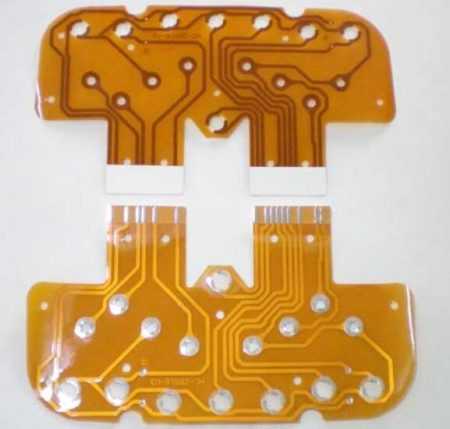

Image 1: Flexible Circuit Manufacturing

Electro plating is capable to provide a reliable metallic surface treatment controlling the thickness and the surface conditions. It is not difficult to manage the plated metal surface shiny or non-shiny. An issue is the all of the metal pad must be connected to the electrodes. It is not a big issue for the simple cable type flexible circuits, which have mostly parallel lines. But it is an serious issue SMT type circuits what have electrically isolated termination pads. They need supplemental lines for only electro plating, and they should be cut after the process.

Electroless plating has less limitation in its application. The plated metals are deposited uniformly for all bare terminals even though they are electrically isolated. On the other hand, electroless plating process has several limitations to control the thickness and the quality of the plated metals. A long processing time and high cost solutions cause the thick plating expensive. Basically, electroless plating is a kind of chemical reaction in an aqueous solution.

Some of the plating solutions are high pH alkaline and they make serious damages for the adhesive layers and coverlay materials. Micro bump arrays will be constructed by advanced processes. Optimized combinations of plating processes can build many kinds of bump shapes at a reasonable cost

Image 2: FPC Flexible Circuit Surface

Flexible circuits have many supplemental constructions other than electrical traces to optimize their capabilities. The stiffener boards are the major one of them. An issue is that it is difficult to apply full automation to the process of making stiffener boards because of the many varieties. Most of the processes are conducted manually and are labor intensive. Sometimes stiffener boards account for a big percentage of the total manufacturing cost. An adhesive film is laminated on a rigid board with a release sheet first. The boards are then routed by punching or by NC router.

It is a very simple process if the adhesive material is pressure-sensitive adhesives (PSAs). Each piece of stiffener is placed on the flex circuits with appropriate pressure, mostly by hand.The process is more complicated when a thermo-set type adhesive material is required. A temperature higher than 160°C with a pressure higher than 20 kg/cm2 is required for more than 30 min. A similar heat press used for multilayer circuit boards or film coverlay is necessary. Dummy boards should be prepared to make the pressure uniform. A heat press with a vacuum chamber or autoclave could provide uniform adhesion forirregularly shaped stiffener boards.

Image 3: SUS stifferner for flexible circuit

Simplify Your PCB Journey with XPCB Limited

XPCB Limited simplifies the PCB process for you. With our quick-turnaround prototyping and turnkey PCBA services, we ensure that your projects move forward smoothly and efficiently. Trust our commitment to quality and timeliness as we help you bring your designs to life. Choose XPCB Limited for a hassle-free PCB experience.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2023 - XPCB Limited All Right Reserve