- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

Menu

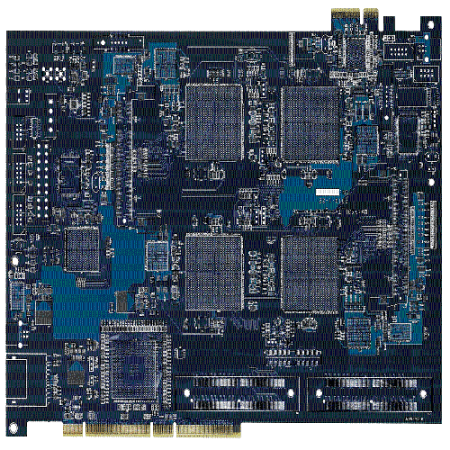

Example 4, check the minimum distance between the edge of the PCB board or the non-tin plated through hole (NPTH) and the trace.

Set to 3mm. When using a machine to solder components to the PCB board, due to the limitations of the machine, it can avoid damaging the traces near the edge of the PCB board.

The pad of the component and the edge of the circuit board should be kept at least 1mm, usually 3mm to 5mm. In addition to preventing cracking, it also reduces the fatigue caused to the pad and prevents the pad from falling off the circuit board due to relative stress.

Normally, the distance between the component through hole and the trace is usually set to 1mm or more (if necessary, it can be set to 0.5mm, not recommended). But for the M3 screw hole, it is usually specified that wiring and components are prohibited within 10mm in diameter. Prevent metal screws from touching the traces and causing short circuits.

The above minimum setting is the design standard of the circuit board, not the setting value of CAM. All of the above inspections can be automatically carried out by setting CAM 3. When the inspection and correction work is completed, data for various processing devices can be generated.

Remark:

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2023 - XPCB Limited All Right Reserve