- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

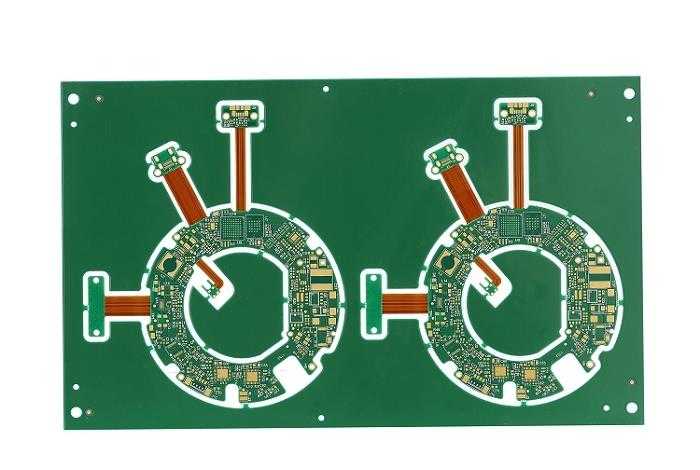

Fundamentally, the benefits of using a flexible PCB in a layout are the ability to bend as well as fold up the circuit and to enable the circuit to bend throughout use. These thin, as well as flexible stack-ups, solve a substantial variety of product packaging problems. But, being thin and also adaptable can likewise offer a couple of obstacles. It is common for a flexible PCB stack-up to consist of support, which is usually most likely to be either a layer of polyimide or a layer of FR4 product, to supply additional assistance and also rigidness in particular locations.

An FR4 stiffener is frequently made use of to sustain a connector. If there is a heavy connector or at least heavy in relation to the weight of the flexible circuit, a piece of FR4 can be related to the flex because of location to provide stability and protect against damages to the copper traces. FR4 stiffeners are likewise made use of to sustain areas in the layout that have a variety of smaller sized, or lighter elements and also the stiffener functions both as assistance for port weight as well as to avoid twisting or flexing in that location, which might put stress on the solder joints.

An FR4 stiffener is frequently made use of to sustain a connector. If there is a heavy connector or at least heavy in relation to the weight of the flexible circuit, a piece of FR4 can be related to the flex because of location to provide stability and protect against damages to the copper traces. FR4 stiffeners are likewise made use of to sustain areas in the layout that have a variety of smaller sized, or lighter elements and also the stiffener functions both as assistance for port weight as well as to avoid twisting or flexing in that location, which might put stress on the solder joints.

An FR4 stiffener can just be an item of FR4 with copper removed made use of as a backer to the flex location, or it might have drilled holes as well as be signed up to the flex to permit thru-hole elements. Sometimes, this “stiffened” flex is confused with an inflexible flex building. There is one substantial difference between a rigid-flex and flex with rigid support; as a support the FR4 is operating only as mechanical assistance, there are no plated via openings giving electrical link between the flex as well as the stiff material.

FR4 supports are added to the flexible circuit as one of the final manufacturing steps and can be applied with either a layer of pressure delicate sticky or a layer of thermal set adhesive. That choice may be driven by end-use or fabricator preference. From a low-priced viewpoint, if completion use is not in an especially rough setting, the stress delicate adhesive application will frequently be a little cheaper. Thermal collection adhesive calls for the flex to be put back in the lamination press to apply the heat and pressure required to heal the adhesive. The added time, as well as labor, can include cost. As a cost-saving pointer, maintaining all the supports the exact same thickness minimizes processing time in fabrication as well as aids to maintain the cost down.

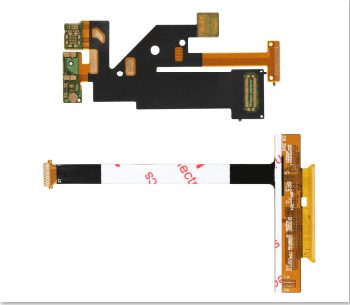

Polyimide stiffeners have a bunch of benefits. They also, can offer support to components as well as protect against bending and folding that might place too much pressure on solder joints. Polyimide stiffeners can be made use of for other functions as well. One typical use a polyimide stiffener is to match a mating thickness demand for insertion type adapters. ZIF connectors are a typical link method with flex styles. These ports have a certain thickness specification as well as limited resistance on that particular density to make sure the connection works. A piece of polyimide can be applied in that stack-up location to arrive at the required thickness while permitting the rest of the flex to continue to be thinner and more flexible. A general rule to remember is to be sure the stiffener and also coverlay end points overlap by a minimum of.030″ to prevent forming a vulnerable point in the flex design.

Polyimide supports additionally carry out other features. As an example, if a flex circuit is going to have something massaging up against it in end usage, a layer of polyimide can be contributed to that location, so the wear and tear is being done to the non-functional piece of polyimide as opposed to straight on the circuit itself.

Polyimide supports additionally carry out other features. As an example, if a flex circuit is going to have something massaging up against it in end usage, a layer of polyimide can be contributed to that location, so the wear and tear is being done to the non-functional piece of polyimide as opposed to straight on the circuit itself.

Polyimide stiffeners can additionally be utilized to change the natural bend area in flex as it is mounted or to develop a bend in a particular location. For example, as the flex is installed, if there is a natural bend area that is interfering with one more item of the system, adding a layer of polyimide will adjust that all-natural bend area to a preferred area. As an additional instance, particular applications benefit by including polyimide pieces on either end of a bend location to both make certain the bend is being carried out in the proper place as well as to assist operators plainly understand where the flexing as well as bending requirement to happen. The areas of polyimide support positioning can be easily tailored.

Polyimide stiffeners can likewise be applied with both pressure-sensitive glue or with thermal set adhesive. Unlike FR4 stiffeners, polyimide supports are commonly applied in the same lamination process action as the polyimide coverlay. This gets rid of an added process action for the supports themselves. Actually, if pressure-sensitive adhesive is called out, it can commonly add price as a result of extra handling being called for. Later on at the same time, the locations with polyimide stiffener are punched or transmitted together with the circuit synopsis removing any kind of enrollment worries.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve