- +86-755-23012705

- Building 3, Jinfeng Industrial Park, Fuyong Street, Baoan District, Shenzhen ,China

- [email protected]

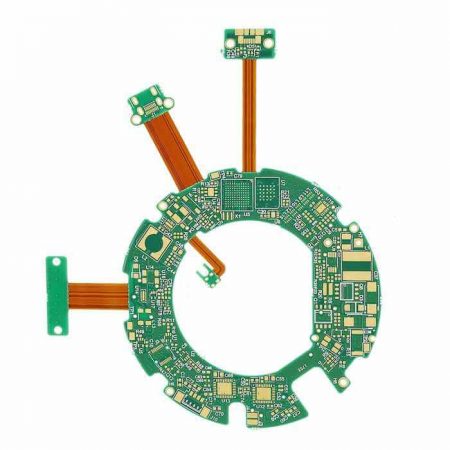

In the world of modern electronics, the evolution of technology demands ever-smaller, more complex, and highly efficient printed circuit boards (PCBs). High-Density Interconnect (HDI) technology has emerged as a cornerstone of advanced PCB manufacturing and assembly, pushing the boundaries of what’s achievable in miniaturization and functionality. By enabling intricate designs and improving manufacturing processes, HDI technology significantly impacts PCBA (Printed Circuit Board Assembly) services. This blog delves into the key aspects of HDI technology, its role in enhancing PCB manufacturing efficiency, and its influence on PCBA service quality.

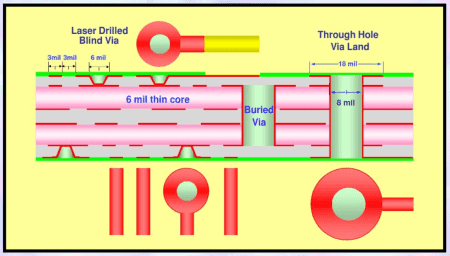

HDI technology represents a specialized branch of PCB manufacturing characterized by its dense interconnects and fine lines. Unlike conventional PCBs, HDI boards feature:

These attributes make HDI technology indispensable for applications where space, performance, and weight are critical, such as smartphones, IoT devices, automotive electronics, and medical equipment.

HDI technology offers unparalleled flexibility in PCB design. Designers can implement complex routing techniques, stack multiple layers, and integrate dense component arrangements, resulting in more compact and efficient boards. This flexibility reduces the need for multiple PCB revisions, saving time and costs.

By minimizing the distance between components and leveraging microvias, HDI technology enhances signal integrity. Reduced signal loss and interference contribute to the overall reliability of electronic devices, especially those requiring high-speed data transmission.

While HDI boards initially incur higher production costs due to advanced materials and processes, their ability to consolidate functionalities reduces the overall product cost. This efficiency benefits industries focused on lightweight and portable devices.

HDI PCBs often incorporate advanced materials and designs that improve heat dissipation. This capability is crucial for high-power devices that generate significant thermal loads, ensuring stable performance and longevity.

The finer details of HDI boards demand highly accurate assembly techniques. Automated equipment, such as pick-and-place machines and precision soldering tools, ensure components are placed and bonded correctly. This precision minimizes errors and enhances product quality.

HDI PCBs support the integration of advanced components like BGAs (Ball Grid Arrays) and CSPs (Chip Scale Packages), which are essential for modern electronics. This compatibility broadens the scope of applications and improves the versatility of PCBA services.

The compact and efficient layout of HDI boards simplifies testing procedures. High-density designs reduce the chances of defects, and when issues do occur, advanced diagnostic tools can pinpoint them swiftly, leading to faster troubleshooting and reduced downtime.

HDI technology promotes sustainable practices by enabling smaller PCBs with fewer materials. Additionally, the improved reliability of HDI PCBs reduces waste from faulty or short-lived products, aligning with eco-conscious manufacturing goals.

The adoption of HDI technology continues to grow across various industries:

HDI technology is at the heart of innovation in PCB manufacturing and PCBA services. Its ability to enhance efficiency, improve quality, and support complex designs makes it a vital enabler of modern electronics. As industries continue to push the limits of technology, HDI will play an increasingly pivotal role, shaping the future of electronic manufacturing. For manufacturers and service providers, investing in HDI capabilities is not just a competitive advantage—it is a necessity to meet the demands of a rapidly evolving market.

Turnkey PCBA Services and Quick-Turn Solutions – XPCB Limited Leads the Way

At XPCB Limited, we lead the way in providing turnkey PCBA services and quick-turn solutions for businesses of all sizes. Our end-to-end capabilities ensure seamless integration of PCB manufacturing, assembly, and testing. With a focus on precision and efficiency, we empower you to deliver superior products to the market faster. Choose XPCB Limited for innovation that moves at your speed.

XPCB Limited is a premium PCB & PCBA manufacturer based in China.

We specialize in multilayer flexible circuits, rigid-flex PCB, HDI PCB, and Rogers PCB.

Quick-turn PCB prototyping is our specialty. Demanding project is our advantage.

Tel : +86-136-3163-3671

Fax : +86-755-2301 2705

Email : [email protected]

© 2024 - XPCB Limited All Right Reserve